PRODUCTS

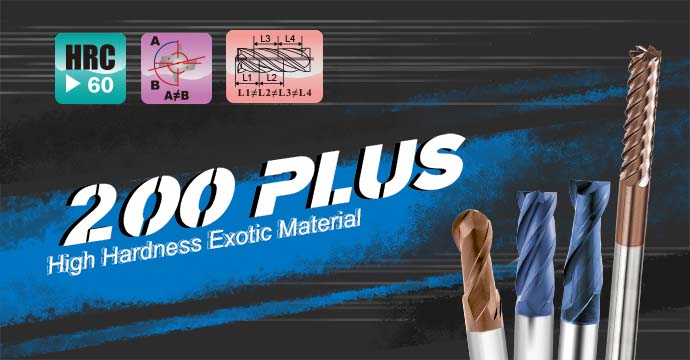

200PLUS - High Hardness Exotic Materials

Product Number:P-SFUMIE, P-SFUET/SFULET, P-SFUVT/SFULVT, P-SFULNT, P-SFUMIB, P-SFUBT, P-SFUBTSX, P-SFULBT, P-SFULNBT, P-SFURTA, P-SFUCR

█Features: ①High Performance for High Hardness Exotic Materials ②Unequal flute spacing and unequal lead design have excellent and long effect of anti-vibration during milling. ③Super Ultra Fine Micro Grain Carbide raw material with the most suitable flute geometry ensure to improve chip disposal and rigidity. ④It's much easier to have finishing procedure on Hardened steel compare to general endmills. █Application: ~HRC65/ Iron, Carbon steel, Cast Iron, Alloy Steel, Tool Steel, Heat treatment Steel,Welding Steel

-

Features

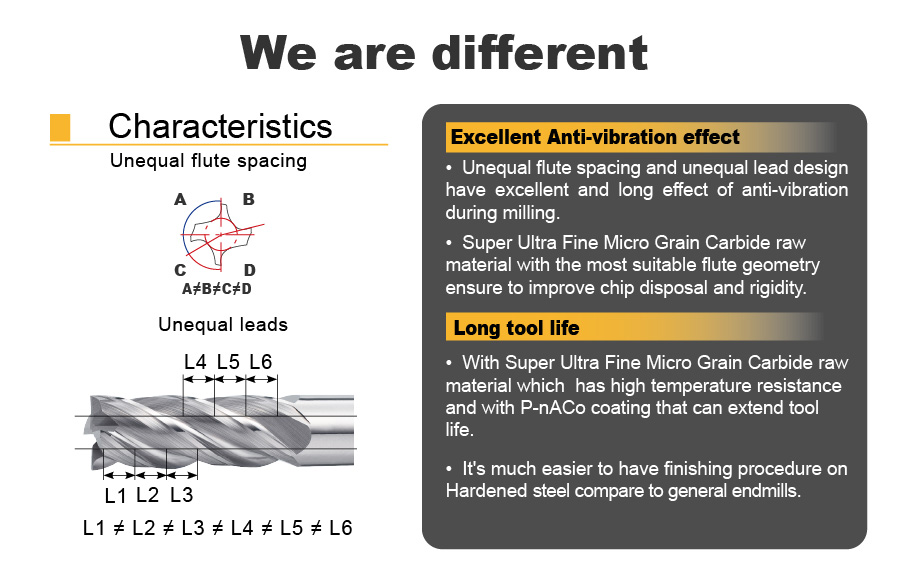

• Unequal flute spacing and unequal lead design have excellent and long effect of anti-vibration during milling.

Characteristic:

Excellent anti-vibration effect

• Super Ultra Fine Micro Grain Carbide raw material with the most suitable flute geometry ensure to improve chip disposal and rigidity.

Long tool life

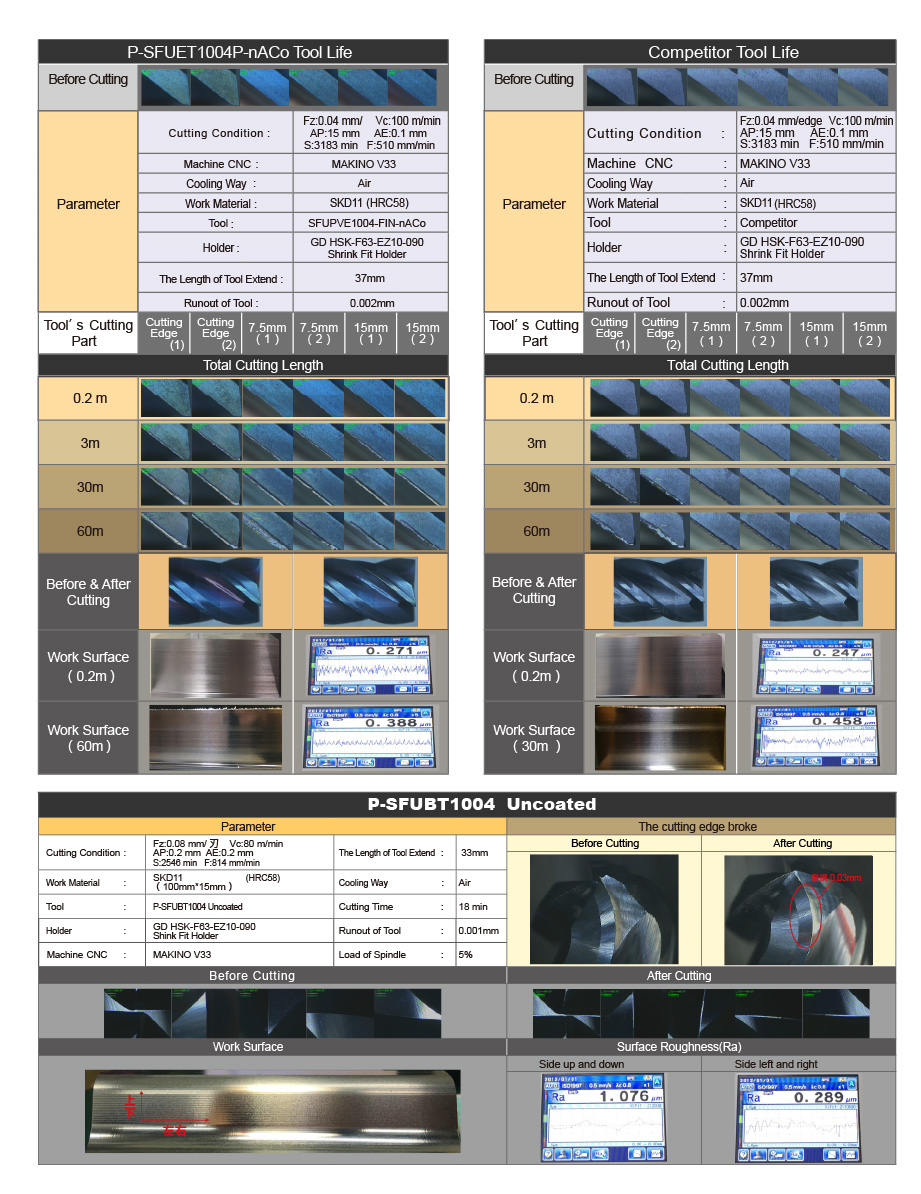

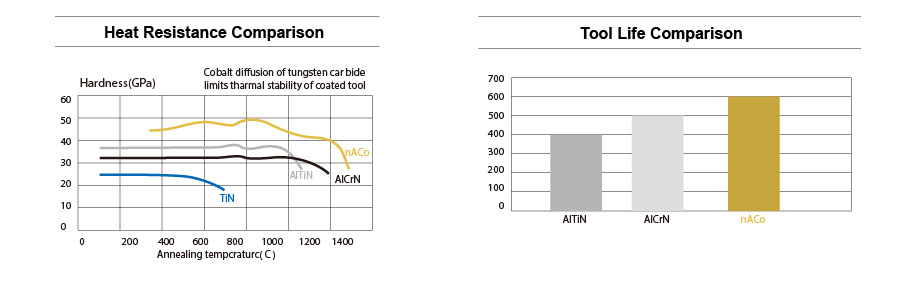

• With Super Ultra Fine Micro Grain Carbide raw material which has high temperature resistance and with P-nACo coating that can extend tool life.

• It's much easier to have finishing procedure on Hardened steel compare to general endmills.

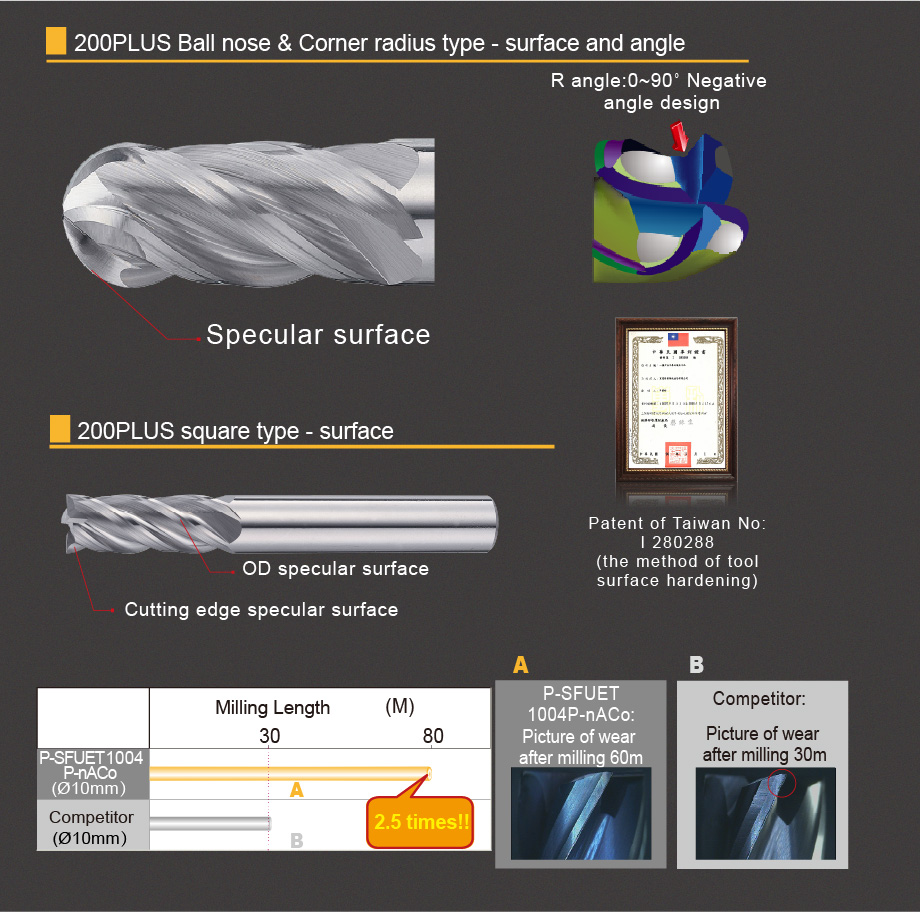

200PLUS Ball nose & Corner radius type - surface and angle

• R angle:0~90˚ Negative angle design

• Specular surface

200PLUS square type - surface

• OD specular surface

• Cutting edge specular surface

-

nACo Coating

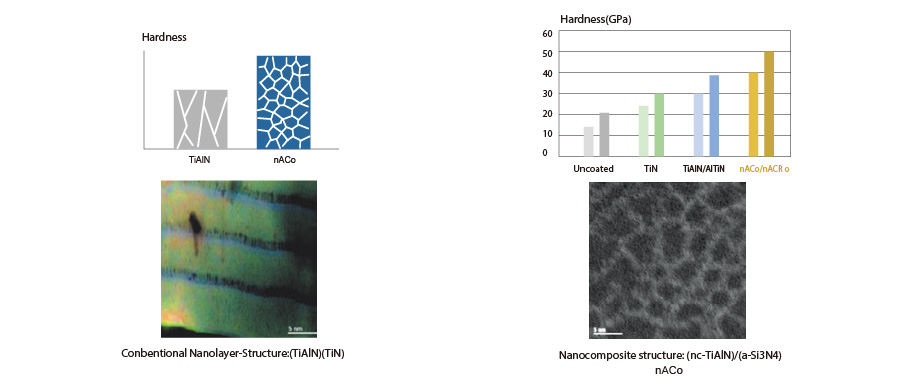

nACo Nanocomposite coating process.- Perfect coating structure.

- High hardness.

- High adhesion.

- Adding Si into nACo structure makes atom structuremore completed with high hard-wearing and tools with more longer life.

AlTiN vs nACo comparisonS.T Coating Typical Thickness(£g) Nanohardness up to (GPa) Max Service Temp(¢J) Friction coefficient AlTiN 2~4 35 800 0.6 nACo 2~4 45 1200 0.35

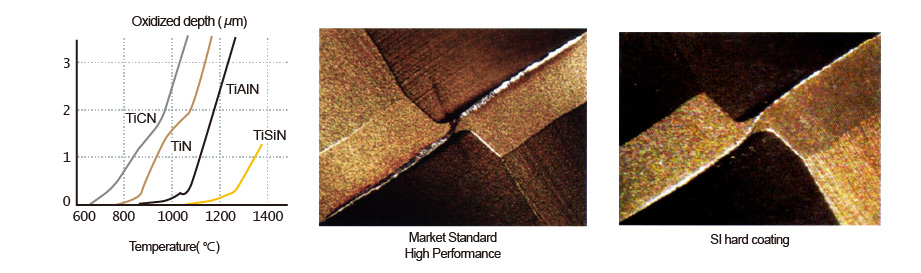

TiSiN Coating

New Nano-composite coating material achieves extraordinary heat resistance and hardness. This is attained due to the new composite layer, consisting of nano-crystal material (Oxidizing temperature:1100℃, Layer hardness:HV 3600). Achieves extraordinary performance in high-speed cutting, and high efficient machining of hardened steel, machining efficiency is more than twice as effective as other manufacturers solid carbide end mills.

Ensuring long life and reliability in hardened steel applications HRC45~55 material examples:1.2080, 1.2344, and 1.2379, ASP Power Steels, High Speed Steels.

The coating generates less heat during cutting; therefore it is well suited to dry machining conditions.

Newly developed TiSiN Coating has excellent oxidation-resistant properties, this achieves:

High speed cutting of hard steels = High Efficiency

Improvement in tool life = Lower tooling costs The newly designed flute geometry increases rigidity, with the improved high radius accuracy producing higher tolerance, and smoother surface finish.

Direct Milling of hardened steel is now possible = Faster production times.

Patent of Taiwan No : I 280288 (the method of tool surface hardening)

-

Type Mode Flutes Diameter Photo Dimension Cutting Condition Miniature Square P-SFUMIE 2 0.2mm~3mm

Download Download Square Type P-SFUET 2 / 4 1mm~25mm

2Flutes

Download

4Flutes

DownloadDownload Long Flute

Square TypeP-SFULET 2 / 4 1mm~25mm

2Flutes

Download

4Flutes

Download2Flutes

Download

4Flutes

DownloadMultiple Flutes

Square TypeP-SFUVT 6 / 8 6mm~25mm

Download Download Multiple Flutes

Long Flute

Square TypeP-SFULVT 6 / 8 6mm~25mm

Download Download Long Neck

Square TypeP-SFULNT 2 / 4 0.5mm~4mm

Download Download Miniature

Ball Nose TypeP-SFUMIB 2 0.3mm~3mm

Download Download Ball Nose Type P-SFUBT 2 / 4 1mm~25mm

2Flutes

Download

4Flutes

DownloadDownload Power Short Flute

Ball Nose TypeP-SFUBTSX 2 1mm~16mm

Download Download Long Shank

Ball Nose TypeP-SFULBT 2 1mm~25mm

Download Download Long Neck

Ball Nose TypeP-SFULNBT 2 0.5mm~4mm

Download Download Corner Radius Type P-SFURTA 4 4mm~12mm

Download Download Long Neck &

Shank Corner

Radius TypeP-SFUCRM 2 / 4 6mm~12mm

2Flutes

Download

4Flutes

Download2Flutes

Download

4Flutes

DownloadPencil Neck

Corner Radius TypeP-SFUCRS 2 / 4 1mm~12mm

2Flutes

Download

4Flutes

Download2Flutes

Download

4Flutes

DownloadLong Neck

Corner Radius TypeP-SFUCR 2 0.4mm~6mm

Download Download 3 Different Flutes

Ball Nose TypeDAB 3 1mm~20mm

Download Download 3 Different Flutes

Corner Radius TypeDAC 3 2mm~20mm

Download Download -

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media