1. Overall lengths are 40mm and 45mm, suitable for lathe machining.

2. 1~16mm & 2/3/4/5/6 flutes for different materials are available.

3. Improve cutting quality and processing speed.

4. High precision and longer tool life.

5. Be stable during the machining process, effectively achieving the anti-vibration effect and increasing the stability of the tool.

-

High Efficiency End Mill for Compound Lathe - 3 Flutes

Diameter: 5-10mm

Unequal Helix 38°-40°-42°

Good at Steel, Stainless Steel, and Titanium, etc.

3 Coating Options: ALTIBN, TiSiN, ZrN-A -

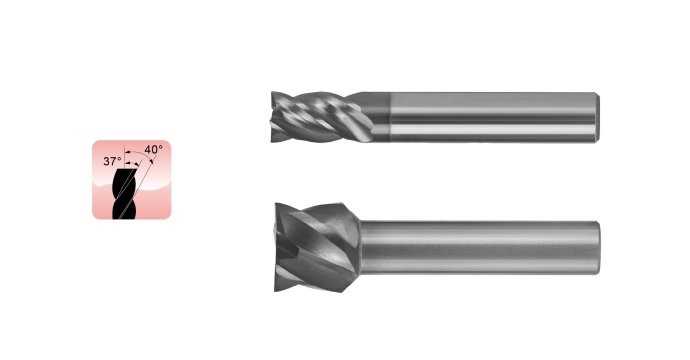

High Efficiency End Mill for Compound Lathe - 4 Flutes

Diameter: 5-10mm

Unequal Helix 38°-40°-42°

Good at Steel, Stainless Steel, and Titanium, etc.

3 Coating Options: ALTIBN, TiSiN, ZrN-A -

High Efficiency End Mill for Compound Lathe - 5 Flutes

Diameter: 5-10mm

Helix 38° & Unequal Flute Spacing

Good at Steel, Stainless Steel, and Titanium, etc.

3 Coating Options: ALTIBN, TiSiN, ZrN-A -

High Efficiency End Mill for Compound Lathe - 6 Flutes

Diameter: 6-12mm

Unequal Helix 40°-42°

Good at Steel with Fine Surface

3 Coating Options: ALTIBN, TiSiN, ZrN-A -

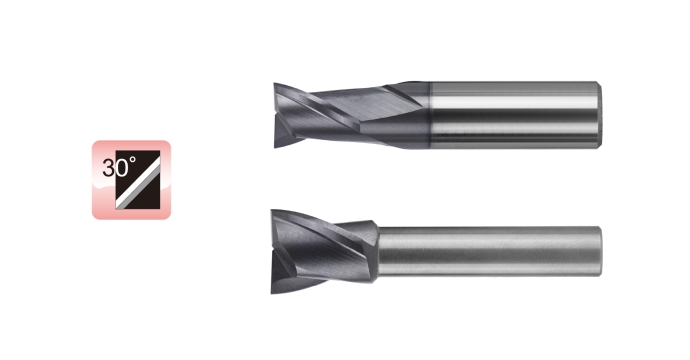

Helix 30° End Mill for Compound Lathe - 2 Flutes

Diameter: 1-16mm

Helix 30°, General Application

3 Coating Options: ALTIBN, TiSiN, ZrN-A -

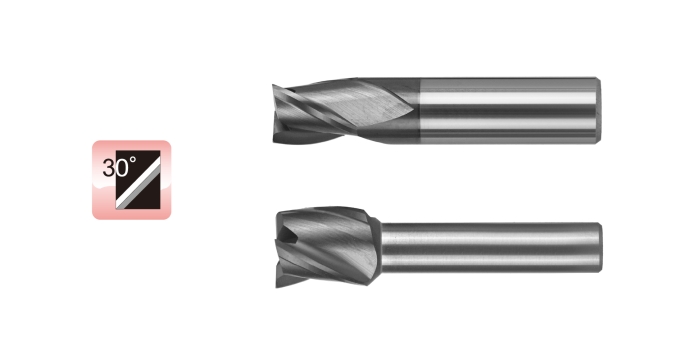

Helix 30° End Mill for Compound Lathe - 3 Flutes

Diameter: 1-16mm

Helix 30°, General Application

3 Coating Options: ALTIBN, TiSiN, ZrN-A -

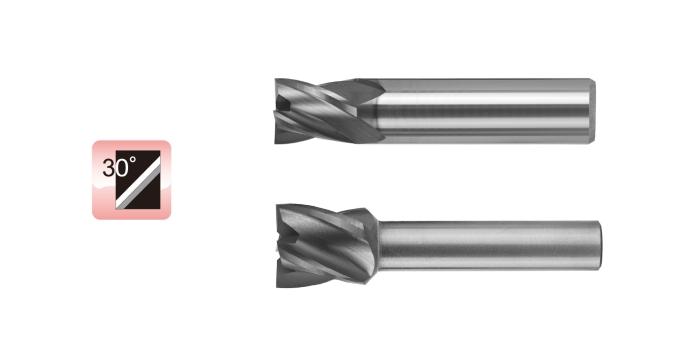

Helix 30° End Mill for Compound Lathe - 4 Flutes

Diameter: 1-16mm

Helix 30°, General Application

3 Coating Options: ALTIBN, TiSiN, ZrN-A -

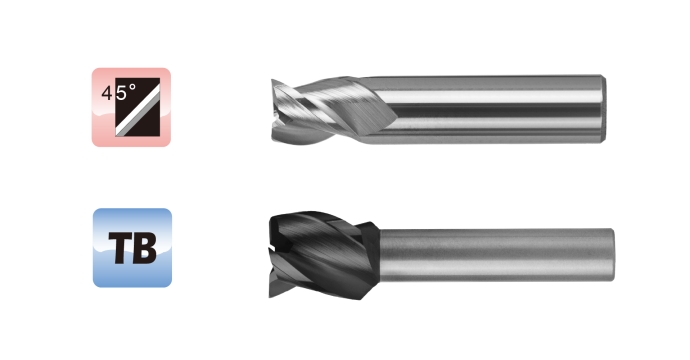

Aluminum End Mill for Compound Lathe - 2 Flutes

Diameter: 2-16mm

Helix 45°, Aluminum Application

2 Coating Options: Uncoated and TB coating (DLC) -

Aluminum End Mill for Compound Lathe - 3 Flutes

Diameter: 2-16mm

Helix 45°, Aluminum Application

2 Coating Options: Uncoated and TB coating (DLC)