PRODUCTS

P-UCR Long Corner Radius Nose End Mill - 4 Flutes

Product Number:P-UCR

█Features: ①Unequal Flute Spacing , Irregular Helix Flutes, Ensures stable machining of difficult-to-cut materials, and achieve high efficient performance. ②Excellent vibration absorption provides stability. ③Less chatter and high efficiency finishing and Reduce metal burr when machining. █Application: ~HRC60/ Iron, Carbon steel, Cast Iron, Alloy Steel, Tool Steel, Heat treatment Steel, Welding Steel

-

400 PLUS Nano End Mills Series General Application

Application: ~HRC60/ Iron, Carbon steel, Cast Iron, Alloy Steel, Tool Steel, Heat treatment Steel, Welding Steel

Main Feature: Ultra Fine Micro Grain Carbide that has high toughness, coating ALTIBN and wear-resisting, non-general titanium aluminum is specialized in milling on M/C high hardness at a high speed and can carry on rough machining get to detailed process directly for heat treatment mould to reduce change times, improve machine flexible rate and shorten producing time.Features

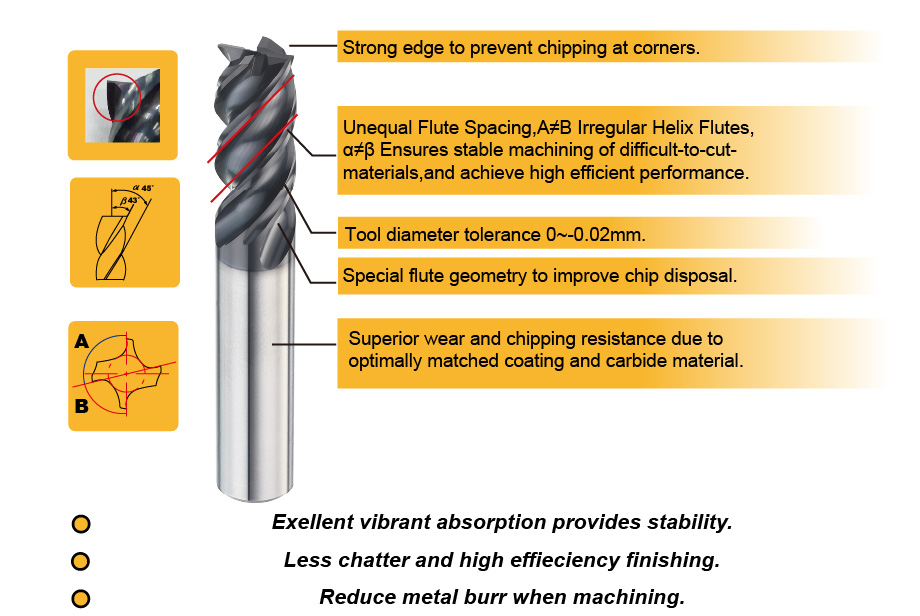

- Strong edge to prevent chipping at corners.

- Unequal Flute Spacing,A≠B Irregular Helix Flutes, α≠β Ensures stable machining of difficult-to-cut-materials, and achieve high efficient performance.

- Tool diameter tolerance 0~-0.02mm.

- Special flute geometry to improve chip disposal.

- Superior wear and chipping resistance due to optimally matched coating and carbide material.

✓ Exellent vibrant absorption provides stability.

✓ Less chatter and high effieciency finishing.

✓ Reduce metal burr when machining.

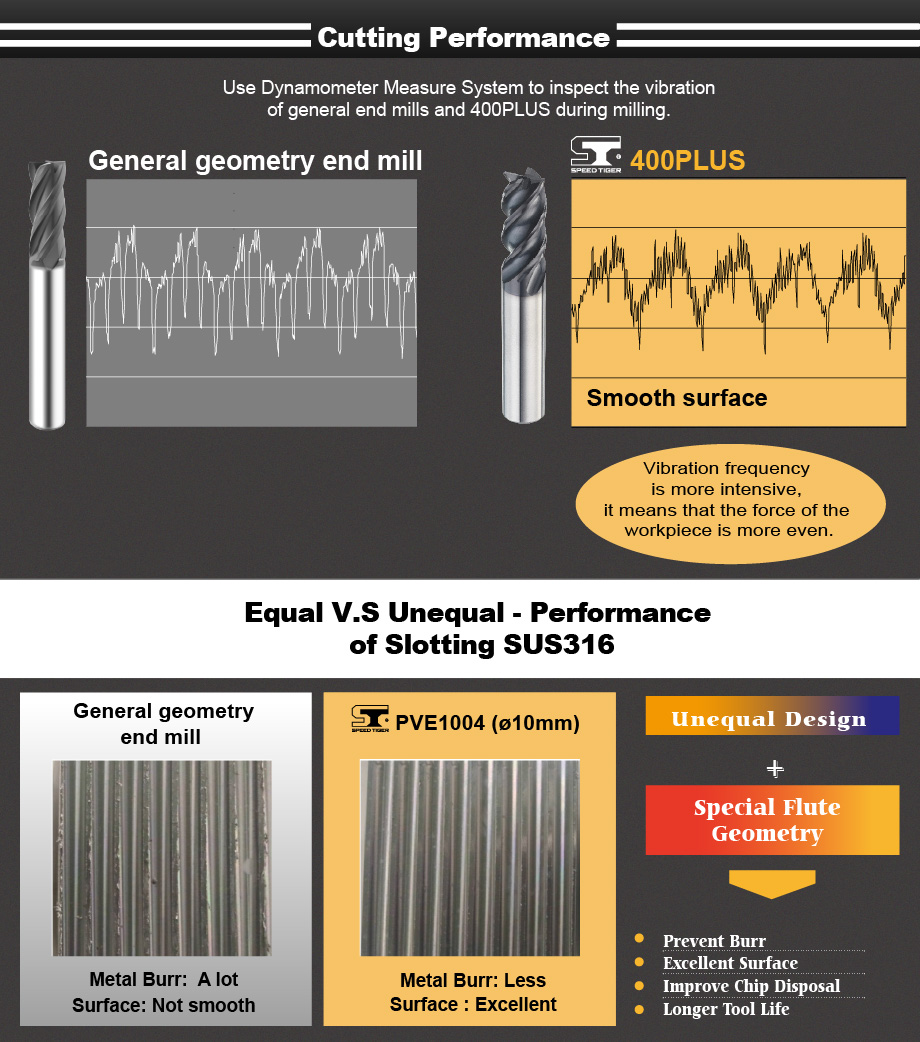

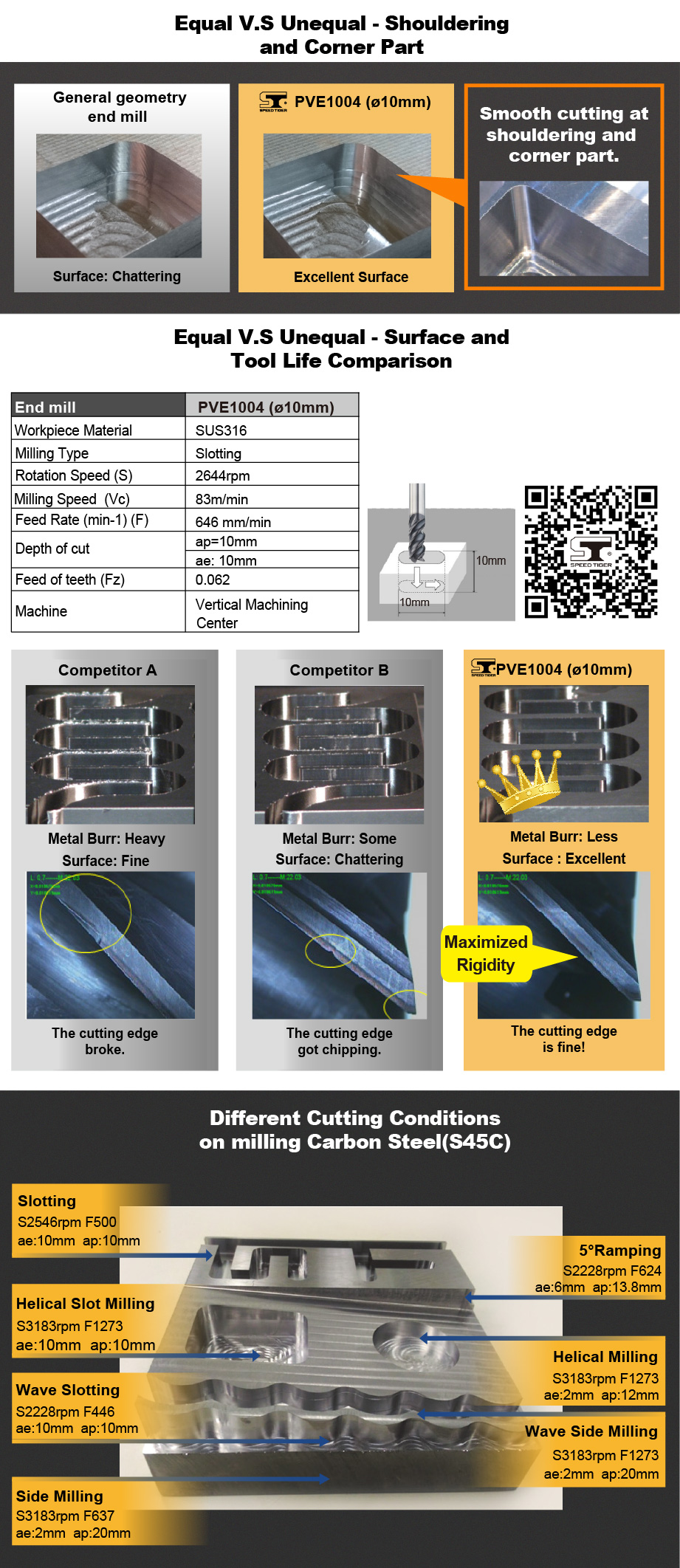

Unequal Design + Special Flute Geometry- Prevent Burr

- Excellent Surface

- Improve Chip Disposal

- Longer Tool Life

Different Cutting Condition on milling Carbon Seel (S45C)- Slotting

- Helical Slot Milling

- Wave Slotting

- Side Milling

- 5°Ramping

- Helical Milling

- Wave Side Milling

Comparison Series Grain Size Hardness

(HRC)Coating Application 200 Nano 0.2μm ~65 TiSiN Super Hard Hardness 400 Nano 0.4μm ~60 nBS High Hardness 600 Nano 0.6μm ~50 AlTiN General Package & Shipping

Delivery :

Generally, it is 5-7 days if the goods are in stock.

It is 15-20 days if the goods are not in stock, it is according to quantity.

https://www.speedtigertools.com/contact/ -

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media

-

-