PRODUCTS

DE - Slotting Side Milling (Soft material)

Product Number:DE, DEM, DEL

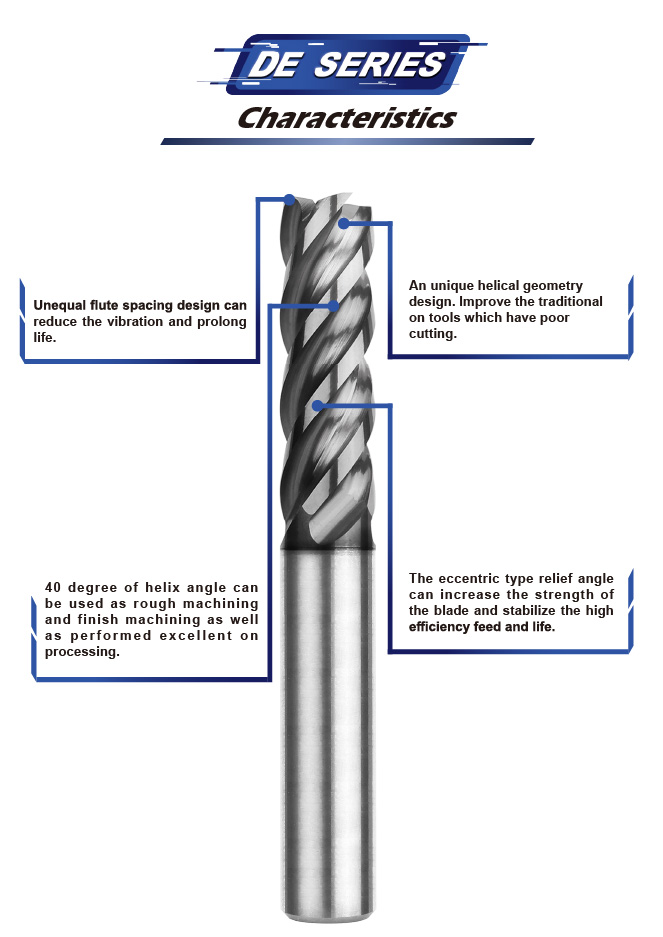

█Features:①Unequal flute spacing design can reduce vibration and prolong life. ②A unique helical geometry design. Improve the traditional tools that have poor cutting. ③40-degree helix angle can be used as rough machining and finish machining as well as performed excellently on processing. ④The eccentric type relief angle can increase the strength of the blade and stabilize the high-efficiency feed and life.

█Application: Excel at working carbon steels (~HB225), alloy steels (HB225~325), pre-hardened steels (up to HRC45), hardened Steels (HRC40~45), stainless steel.

-

Features

- Unequal flute spacing design can reduce vibration and prolong life.

- A unique helical geometry design. Improve the traditional tools that have poor cutting.

- 40-degree helix angle can be used as rough machining and finish machining as well as performed excellent on processing.

- The eccentric type relief angle can increase the strength of the blade and stabilize the high-efficiency feed and life.

Coating Options Speed Tiger is not only the largest cutting tools manufacturer but also the first one that combined milling cutter coating technology in Taiwan. We provide a variety of coating types for different applications, you could easily choose the most suitable coating for your work. For detailed coating information, please refer to the next tab.

Package & Shipping

Delivery :

Generally, it is 5-7 days if the goods are in stock.

It is 15-20 days if the goods are not in stock, it is according to quantity.

http://www.speedtigertools.com/inquiry/ -

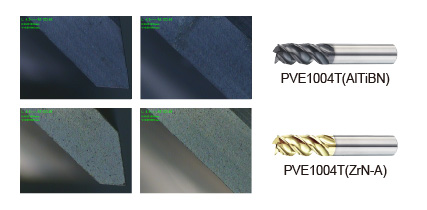

ALTIBN Coating

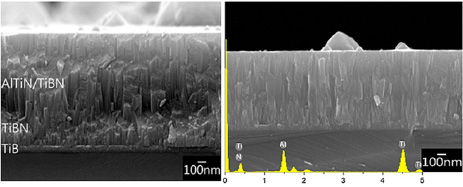

Coating Structural Analysis-SEM

Normal Temperature Mechanical Analysis

In normal temperature mechanical analysis,the performance of AlTiBN is superior to AlTiN in hardness, wear rate and coating roughness.Hardness (Hv) Impact of Diameter Lc2-Lc1 Wear Rate Roughness (µm) AlTiN 3672 305(um) 8.28N 6.49x10-6 0.233 AlTiBN 4088 280.9(um) 17.6N 5.11x10-6 0.166

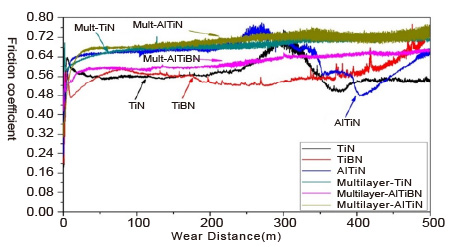

The Oxidation Wear of 700°C

Fiction Coefficient Wear Distance Wear rate TiN 0.5662 316.3 6.4x10-6 TiBN 0.5664 281.2 5.69x10-6 AlTiN 0.6402 281.4 4.97x10-6 Multi-TiN 0.686 277.4 4.82x10-6 ALTIBN 0.618 281.8 4.66x10-6 Mult-ALTiN 0.7014 290.1 5.5x10-6

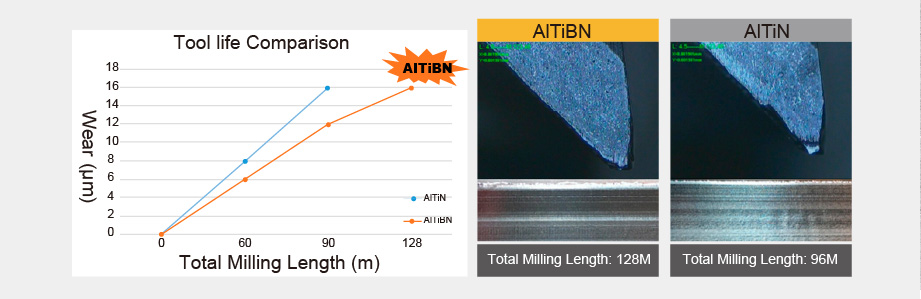

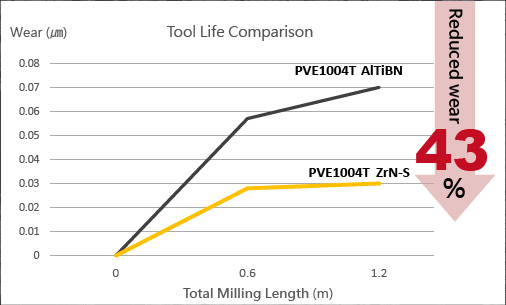

Tool Life Comparison and Cutting Edges

Milling Type Side Milling Feed Rate 1082mm/min Work Piece S45C Depth of Cut ap=20 ae=1.2 Tool Size 10mm x 30 x 75L Coolant Way Air Rotation Speed 3183 rpm CNC Machine CNC YCM FV102A TiSiN Coating

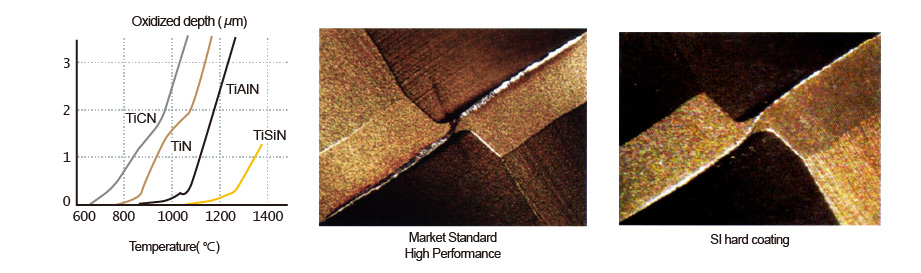

New Nano-composite coating material achieves extraordinary heat resistance and hardness. This is attained due to the new composite layer, consisting of nano-crystal material (Oxidizing temperature:1100℃, Layer hardness:HV 3600). Achieves extraordinary performance in high-speed cutting, and high efficient machining of hardened steel, machining efficiency is more than twice as effective as other manufacturers solid carbide end mills.

Ensuring long life and reliability in hardened steel applications HRC45~55 material examples:1.2080, 1.2344, and 1.2379, ASP Power Steels, High Speed Steels.

The coating generates less heat during cutting; therefore it is well suited to dry machining conditions.

Newly developed TiSiN Coating has excellent oxidation-resistant properties, this achieves:

High speed cutting of hard steels = High Efficiency

Improvement in tool life = Lower tooling costs The newly designed flute geometry increases rigidity, with the improved high radius accuracy producing higher tolerance, and smoother surface finish.

Direct Milling of hardened steel is now possible = Faster production times.

Patent of Taiwan No : I 280288 (the method of tool surface hardening)

ZrN-A Coating

Block resistance- Suitable for High Speed machining with both dry and wet cutting way.

- Hardness 2800~3000 HV

- Coefficient of friction: 0.3

- Oxidation Temp: 800~900°C

- High performance coating(Light golden)

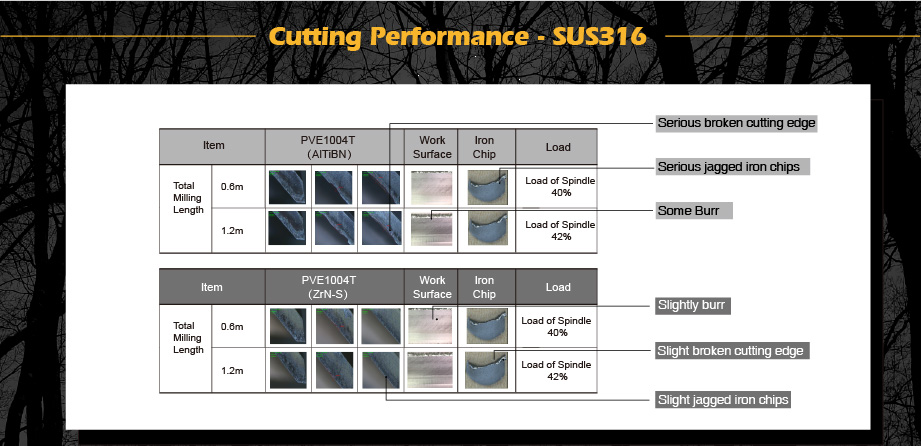

Measured comparison-SUS316

Before the tool is used

Parameter Tool(Coating) PVE 1004 ZrN-A Cutting Material SUS316 Rotation Speed (S) 2644 rpm Milling Speed (Vc) 100 m/min Feed Rate (F) 646 mm/min Depth of cut ap=10mm / ae=10mm (Fz) Feed of teeth 0.062 Machine YCM FV102A Holder BT40 Shrink fit holder The length of Tool Extend 37mm Cooling Way Water

Parameter Tool(Coating) PVE 1004 ZrN-S Cutting Material SUS316 Rotation Speed (S) 2644 rpm Milling Speed (Vc) 100 m/min Feed Rate (F) 646 mm/min Depth of cut ap=10mm / ae=10mm (Fz) Feed of teeth 0.062 Machine YCM FV102A Holder BT40 Shrink fit holder The length of Tool Extend 37mm Cooling Way Water

Coating Total Milling Length (m) 0.6m 1.2m ALTIBN 0.057µm 0.07µm ZrN-S 0.0µm 0.03µm

-

Shape Flute Type Mode Diameter Photo Spec. & Cutting Condition Square 4 dX2.5 DE 1.0mm~20.0mm

Download Square 4 dX3 DEL 4.0mm~20.0mm Square 4 dX4.5 DEVL 6.0mm~20.0mm -

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media