PRODUCTS

IPVR1T Carbide Corner Radius End Mill for Titanium

Product Number:IPVR1T

█Features: ①UNEQUAL FLUTE SPACING AND HELIX DESIGN - Anti-Vibration, Improves Chip Disposal, Prevents Burr, Excellent Surface. ②HIGH PERFORMANCE FOR HARD MATERIALS - Micro Grain Carbide that is very tough, resists wear, and is good for cutting. ③ZrN-A COATING - Zirconium nitride (ZrN) +Titanium aluminum boron nitride (AlTiBN) coating lubricates the end mill for stability at high temperature and superior wear resistance at high cutting speeds, offering better heat resistance than TiAlN, TiN or TiCN coatings. ④HIGH QUALITY - Flutes ground by a world-class ISO-9001 Factory; Great performance at a competitive price. █Application: Nickel alloy / Inconel Alloy.

-

Features

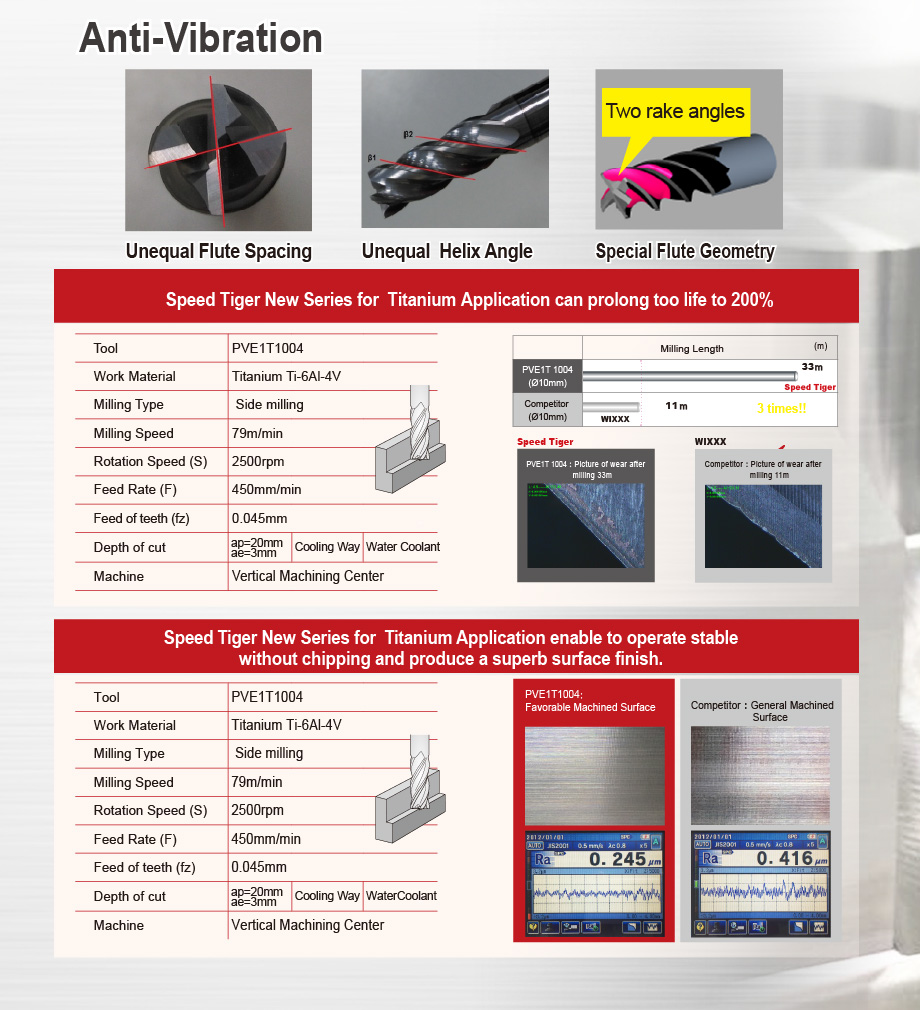

Anti-vibration- Unequal Flute Spacing

- Unequal Helix Angle

- Special Flute Geometry

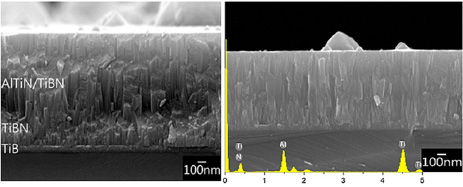

ALTIBN Coating

Coating Structural Analysis-SEM

Normal Temperature Mechanical Analysis

In normal temperature mechanical analysis,the performance of AlTiBN is superior to AlTiN in hardness, wear rate and coating roughness.Hardness (Hv) Impact of Diameter Lc2-Lc1 Wear Rate Roughness (µm) AlTiN 3672 305(um) 8.28N 6.49x10-6 0.233 AlTiBN 4088 280.9(um) 17.6N 5.11x10-6 0.166

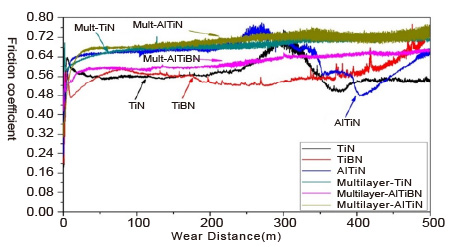

The Oxidation Wear of 700°C

Fiction Coefficient Wear Distance Wear rate TiN 0.5662 316.3 6.4x10-6 TiBN 0.5664 281.2 5.69x10-6 AlTiN 0.6402 281.4 4.97x10-6 Multi-TiN 0.686 277.4 4.82x10-6 ALTIBN 0.618 281.8 4.66x10-6 Mult-ALTiN 0.7014 290.1 5.5x10-6

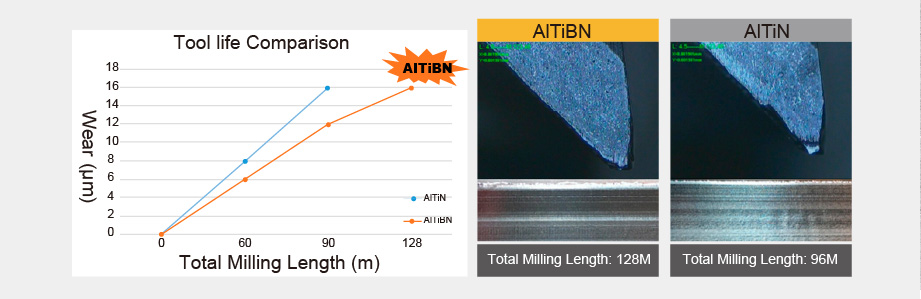

Tool Life Comparison and Cutting Edges

Milling Type Side Milling Feed Rate 1082mm/min Work Piece S45C Depth of Cut ap=20 ae=1.2 Tool Size 10mm x 30 x 75L Coolant Way Air Rotation Speed 3183 rpm CNC Machine CNC YCM FV102A Customer Reviews

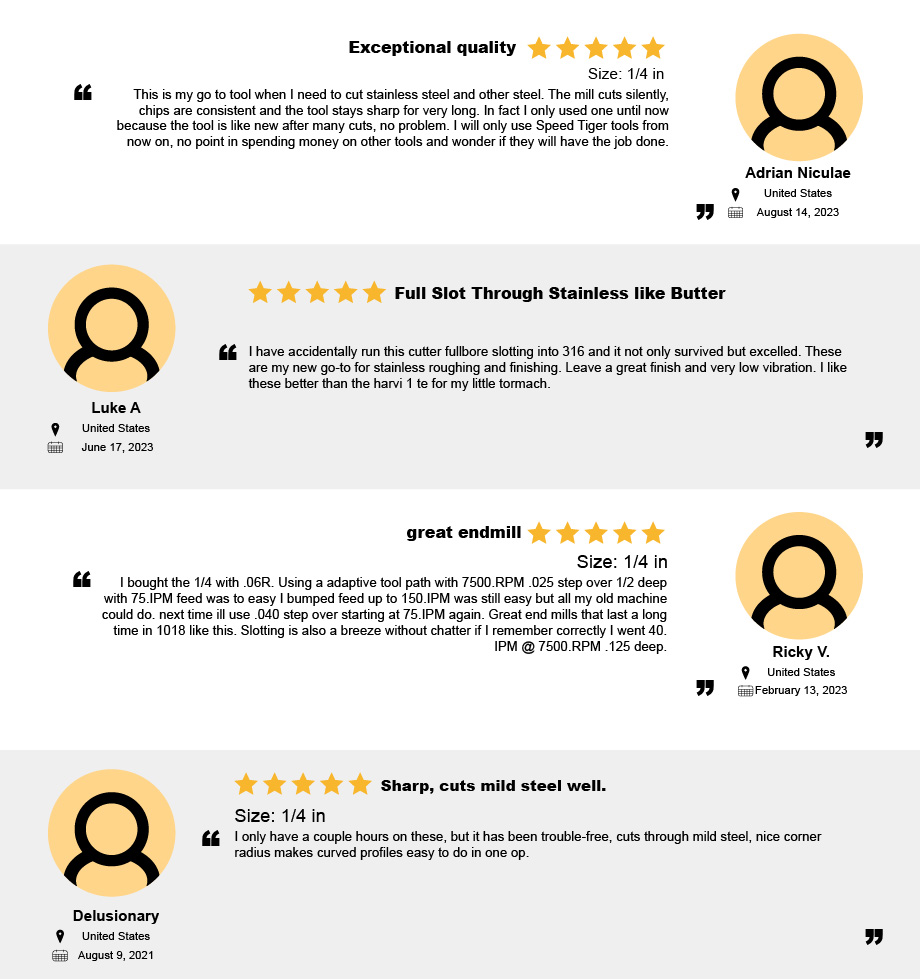

Exceptional quality ⭐⭐⭐⭐⭐

Size:1/4 in

"This is my go to tool when I need to cut stainless steel and other steel. The mill cuts silently, chips are consistent and the tool stays sharp for very long. In fact I only used one until now because the tool is like new after many cuts, no problem. I will only use Speed Tiger tools from now on, no point in spending money on other tools and wonder if they will have the job done." Adrian Niculae from United States on August 14, 2023

Full Slot Through Stainless like Butter ⭐⭐⭐⭐⭐

Size:3/8 in

"I have accidentally run this cutter fullbore slotting into 316 and it not only survived but excelled. These are my new go-to for stainless roughing and finishing. Leave a great finish and very low vibration. I like these better than the harvi 1 te for my little tormach." Luke A from United States on June 17, 2023

great endmill ⭐⭐⭐⭐⭐

Size:1/4 in

"I bought the 1/4 with .06R. Using a adaptive tool path with 7500.RPM .025 step over 1/2 deep with 75.IPM feed was to easy I bumped feed up to 150.IPM was still easy but all my old machine could do. next time ill use .040 step over starting at 75.IPM again. Great end mills that last a long time in 1018 like this. Slotting is also a breeze without chatter if I remember correctly I went 40. IPM @ 7500.RPM .125 deep." Ricky V. from United States on February 13, 2023

Sharp, cuts mild steel well. ⭐⭐⭐⭐⭐

Size:1/4 in

"I only have a couple hours on these, but it has been trouble-free, cuts through mild steel, nice corner radius makes curved profiles easy to do in one op." Delusionary from United States on August 9, 2021 -

MODE Diameter Corner Radius Flute

LengthFull

LengthShank

DiameterFlutes Specification

DownloadIPVR1T1/4”0.015”4 1/4'' R.015 9/16'' 2-1/2'' 1/4'' 4 Download

Cutting

Condition

DownloadIPVR1T1/4”0.03”4 1/4'' R.030 9/16'' 2-1/2'' 1/4'' 4 IPVR1T1/4”0.06”4 1/4'' R.060 9/16'' 2-1/2'' 1/4'' 4 IPVR1T5/16”0.015”4 5/16'' R.015 11/16'' 2-1/2'' 5/16'' 4 IPVR1T5/16”0.03”4 5/16'' R.030 11/16'' 2-1/2'' 5/16'' 4 IPVR1T5/16”0.06”4 5/16'' R.060 11/16'' 2-1/2'' 5/16'' 4 IPVR1T3/8”0.02”4 3/8'' R.020 13/16'' 2-1/2'' 3/8'' 4 IPVR1T3/8”0.03”4 3/8'' R.030 13/16'' 2-1/2'' 3/8'' 4 IPVR1T3/8”0.06”4 3/8'' R.060 13/16'' 2-1/2'' 3/8'' 4 IPVR1T3/8”0.09”4 3/8'' R.090 13/16'' 2-1/2'' 3/8'' 4 IPVR1T1/2”0.02”4 1/2'' R.020 1'' 3'' 1/2'' 4 IPVR1T1/2”0.03”4 1/2'' R.030 1'' 3'' 1/2'' 4 IPVR1T1/2”0.06”4 1/2'' R.060 1'' 3'' 1/2'' 4 IPVR1T1/2”0.09”4 1/2'' R.090 1'' 3'' 1/2'' 4 IPVR1T1/2”0.125”4 1/2'' R.125 1'' 3'' 1/2'' 4 IPVR1T5/8”0.03”4 5/8'' R.030 1-1/4'' 3-1/2'' 5/8'' 4 IPVR1T5/8”0.06”4 5/8'' R.060 1-1/4'' 3-1/2'' 5/8'' 4 IPVR1T5/8”0.09”4 5/8'' R.090 1-1/4'' 3-1/2'' 5/8'' 4 IPVR1T5/8”0.125”4 5/8'' R.125 1-1/4'' 3-1/2'' 5/8'' 4 -

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media