PRODUCTS

ISE Square End Mill - 2 Flutes

Product Number:ISE

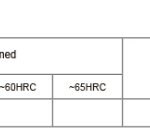

█Features: ①HIGH PERFORMANCE FOR HARD MATERIALS - Cutter is made of Micro Grain Carbide that is very tough, resists wear and offers high cutting performance. ②AlTiBN COATING - Titanium aluminum boron nitride (AlTiBN) coating lubricates the end mill for stability at high temperature and superior wear resistance at high cutting speeds, offering better heat resistance than TiAlN, TiN or TiCN coatings. ③ HIGH-QUALITY - Flutes ground by a world-class ISO-9001 Factory; Great performance at a competitive price. █Application: GENERAL APPLICATION CUTTER - Speed Tiger 600 Nano carbide tools excel at working carbon steels (~HB225), alloy steels (HB225~325), pre-hardened steels (up to HRC45), hardened Steels (HRC40~45), cast iron.

-

Features

Product Feature

Cutter is made of micro grain carbide that is very tough, resists wear and offers high cutting performance.

- High heat resistance

- High stability

- High performance

ISE-2T is ideal for machining carbon steel, alloy steel, and Pre-hardened steel up to HRC50.

ISE-2T is ideal for machining carbon steel, alloy steel, and Pre-hardened steel up to HRC50.

Customer reviews Great product. Be sure to choose the proper number of flutes for your intended purpose.⭐⭐⭐⭐⭐

Amazon review

I'm very very surprised. I'll buy these again and again.⭐⭐⭐⭐⭐

Item Package Quantity: 5 | Size:1/8 in

I needed to cut some cold-rolled steel on my desktop CNC. Typically steel is not a material you want to cut on a desktop CNC which tend not to be as rigid as necessary. But with some well-thought out feeds and speeds it is possible. I bought the 2 Flute - ISE1/8"2T set of end mills. And I'm very impressed. I ran the machine at 15k rpm, 5mm DOC, and 150mm feed rate. The end mill was outstanding. It didn't chatter, it cut smooth as butter and the finishing pass left a very nice finish on the edge of the cuts. You know what else, the packaging the end mills came in was very nice too. I know that isn't important but most manufactures don't even think about packaging. To give some perspective I use mostly Spektra end mills from Amana Tools,and Whiteside end mills, both for wood. These Speed Tiger end mills were my first introduction to cutting steel.

-----Mark from United State comment on November 26,2020

Strong, sharp, and gets it done. Completed 2 lower 80% AR receivers⭐⭐⭐⭐⭐

Item Package Quantity: 5 | Size: 1/8 in

I used and abused this bit to cut out and mill two AR lowers on my drill press. It started to dull on the end of the Second one. However, I truly abused it cutting the aluminum out and it performed extremely well. Remember that you have to turn the speed up on your drill press for it to function with these bits properly. It still cuts, just a little dulled by the amount of use. Much material is removed to complete the 80% lower receivers. I would recommend it and will certainly buy more for future builds. I had no issues with it breaking, luckily since I only had the one. Also the length is great for the job I did.

-----J-Son's Auto and Racing from United State comment on July 20,2020

Way better than you'd expect!⭐⭐⭐⭐⭐

Item Package Quantity: 5 | Size: 1/4 in

Incredibly impressed with these bits. We were cutting 10 round tabletops in hard maple. I purchased a $35 whiteside upcut bit for the routing, it snapped after 30 minutes of use. I figured if we're going to be snapping hits then I'd buy a bulk pack of cheap. I installed the first of these bits and it lasted through the other nine tops. The cut quality wasn't perfect, but tear out was minimal and everything was easily cleaned up in post sanding. Highly recommend them for fast production work of hardwoods!

-----Willy G. from United State comment on January 14,2020

Item Package Quantity: 1 | Size: 5/16 in

( Product is wonderful. Exceptional quality and performance. The 2-flute model was the perfect choice for my needs, since I was cutting into a soft piece which produced a large amount of swarf. The excess material was able to easily come up along the bit and away from the cutting area to then be blown away with an air hose. More flutes would've made this job much harder or close to impossible for me. Very pleased.

-----Amanda Zdanis from United State comment on September 15, 2019 -

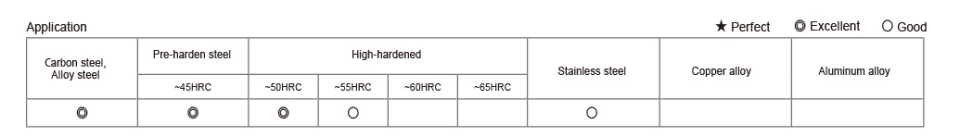

ALTIBN Coating

Coating Structural Analysis-SEM

Normal Temperature Mechanical Analysis

In normal temperature mechanical analysis,the performance of AlTiBN is superior to AlTiN in hardness, wear rate and coating roughness.Hardness (Hv) Impact of Diameter Lc2-Lc1 Wear Rate Roughness (µm) AlTiN 3672 305(um) 8.28N 6.49x10-6 0.233 AlTiBN 4088 280.9(um) 17.6N 5.11x10-6 0.166

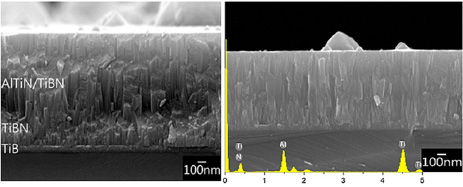

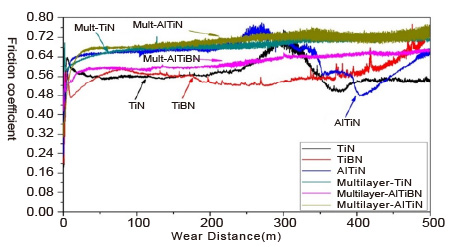

The Oxidation Wear of 700°C

Fiction Coefficient Wear Distance Wear rate TiN 0.5662 316.3 6.4x10-6 TiBN 0.5664 281.2 5.69x10-6 AlTiN 0.6402 281.4 4.97x10-6 Multi-TiN 0.686 277.4 4.82x10-6 ALTIBN 0.618 281.8 4.66x10-6 Mult-ALTiN 0.7014 290.1 5.5x10-6

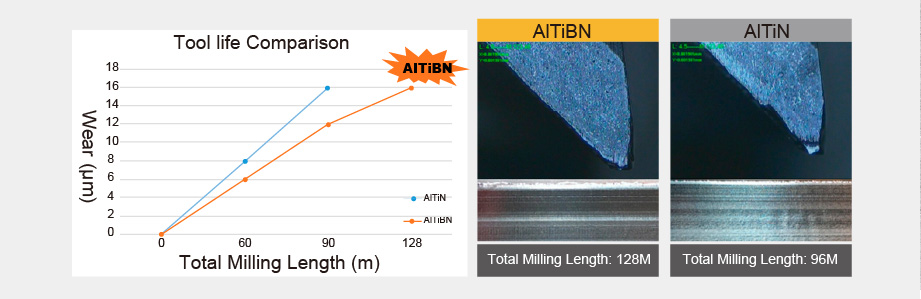

Tool Life Comparison and Cutting Edges

Milling Type Side Milling Feed Rate 1082mm/min Work Piece S45C Depth of Cut ap=20 ae=1.2 Tool Size 10mm x 30 x 75L Coolant Way Air Rotation Speed 3183 rpm CNC Machine CNC YCM FV102A -

Series Catalogue Download

MODEDiameter Flute

LengthFull

LengthShank

DiameterFlutes Specification

DownloadISE1/16"2T 1/16'' 3/16'' 1-1/2'' 1/8'' 2 Download

Cutting

Condition

DownloadISE5/64"2T 5/64'' 3/16'' 1-1/2'' 1/8'' 2 ISE3/32"2T 3/32'' 9/32'' 1-1/2'' 1/8'' 2 ISE7/64"2T 7/64'' 3/8'' 1-1/2'' 1/8'' 2 ISE1/8"2T 1/8'' 3/8'' 1-1/2'' 1/8'' 2 SE3/16"2T 3/16'' 5/8'' 2'' 3/16'' 2 ISE1/4"2T 1/4'' 3/4'' 2-1/2'' 1/4'' 2 ISE5/16"2T 5/16'' 13/16'' 2-1/2'' 5/16'' 2 ISE3/8"2T 3/8'' 1'' 2-1/2'' 3/8'' 2 ISE1/2"2T 1/2'' 1'' 3'' 1/2'' 2 ISE5/8"2T 5/8'' 1-1/4'' 3-1/2'' 5/8'' 2 -

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media