PRODUCTS

Double Removal Rate-BFR Corner Radius End Mill - 2 Flutes

Product Number:BFR

█Features: ① Smooth radius relief, superior wear and chipping resistance due to optimally matched coating and carbide material. ② Shorten by 20~50% of machining time. ③Developed Nano SH Coating of high adhesion and high hardness is adopted. █Application: ~HRC60/ Iron, Carbon steel, Cast Iron, Alloy Steel, Tool Steel, Heat treatment Steel, Welding Steel

-

Super High Hardness & Super High Speed Cutting End Mills Series

Application: ~HRC60/ Iron, Carbon steel, Cast Iron, Alloy Steel, Tool Steel, Heat treatment Steel, Welding SteelFeatures

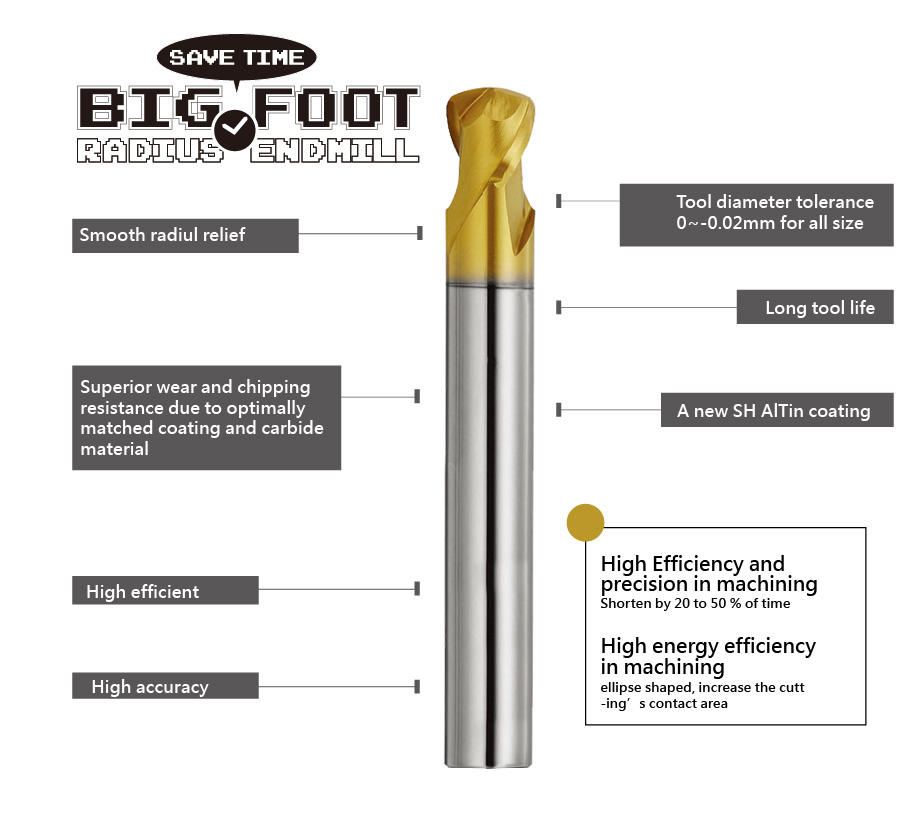

- Smooth radiul relief

- Superior wear and chipping resistance due to optimally matched coating and carbide material

- High efficient

- High accuracy

- Tool diameter tolerance

- 0~-0.02mm for all size

- Long tool life

- A new SH AlTin coating

High Efficiency and precision in machining

Shorten by 20 to 50 % of time

High energy efficiency in machining

Ellipse shaped, increase the cutting’s contact area

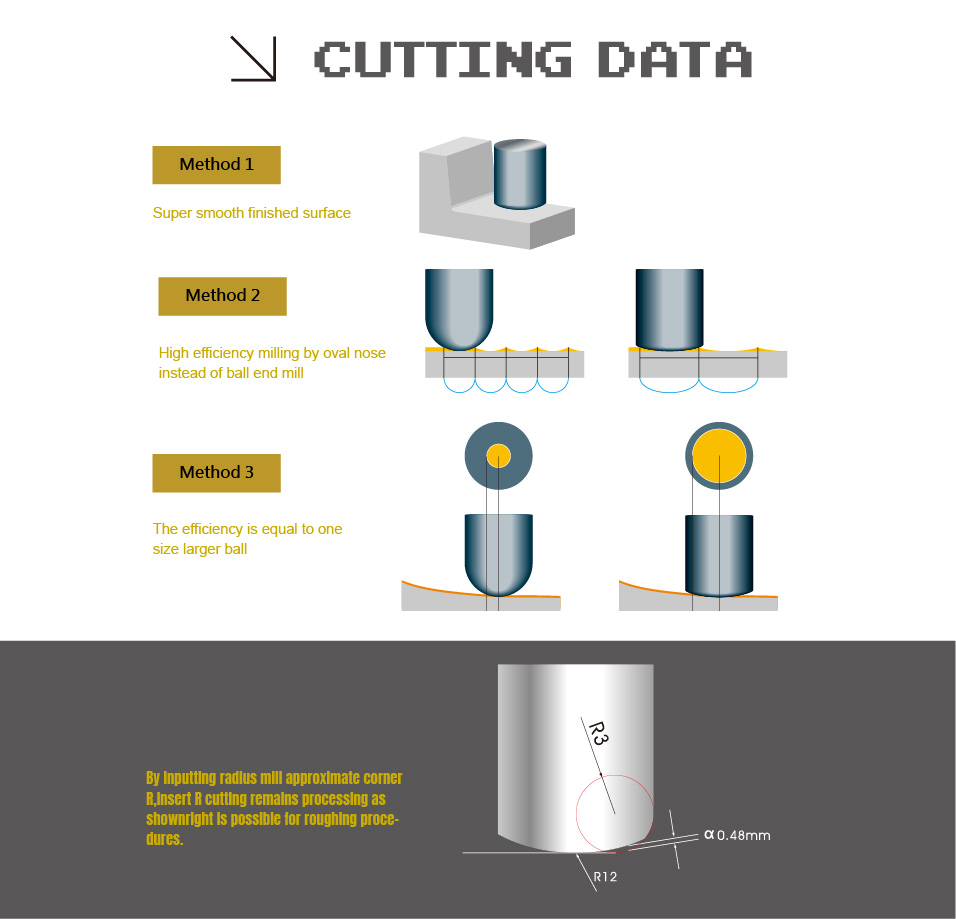

Cutting Data

Method 1

Super smooth finished surface

Method 2

High efficiency milling by oval nose instead of ball end mill

Method 3

The efficiency is equal to one size larger ball

By inputting radius mill approximate corner R,insert R cutting remains processing as shownright is possible for roughing procedures.

SH Coating

Coating Material System Application Typical Thickness (µm) Hardness (HV) Oxidation Temp. (°C) Coefficient of Friction Color AlTiN SH Multilayer Nano High speed machining, High Hardness 2~4 3600 1200 0.34 Golden AlTiN SS Multilayer Nano High speed machining, dry or wet cutting, soft steel 2~4 3300 900 0.30 Silver

Why do we coat “Super Hard Altin”? We called SH Altin!BFR demand coatings SH because SH coatings:

Reduce customers costs- Longer tool life

- Less manufacturing down time

- Tools work faster / more production per hour

- Reduced tool inventories

- Reduction or elimination of coolants / release agents

Improve quality- Less scrap

-

SH Coating

Coating Material System Application Typical Thickness (µm) Hardness (HV) Oxidation Temp. (°C) Coefficient of Friction Color AlTiN SH Multilayer Nano High speed machining, High Hardness 2~4 3600 1200 0.34 Golden AlTiN SS Multilayer Nano High speed machining, dry or wet cutting, soft steel 2~4 3300 900 0.30 Silver

Why do we coat “Super Hard Altin”? We called SH Altin!BFR demand coatings SH because SH coatings:

Reduce customers costs- Longer tool life

- Less manufacturing down time

- Tools work faster / more production per hour

- Reduced tool inventories

- Reduction or elimination of coolants / release agents

Improve quality- Less scrap

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media

-