PRODUCTS

FD Flat Drill 2xD 4xD

Product Number:2FD, 4FD - 2xD & 4xD Carbide Flat Drill - Without Coolant Hole , Size Range: 3mm~16mm / 3mm~14mm , Point Angle: 180°

█Features: ①Special geometry design - Provides superior chip evacuation, allows break-chips effectively and enhance the cutting edge. █Application: nACRo - Carbon steel, Alloy steel , ZrN-A - Stainless steel

-

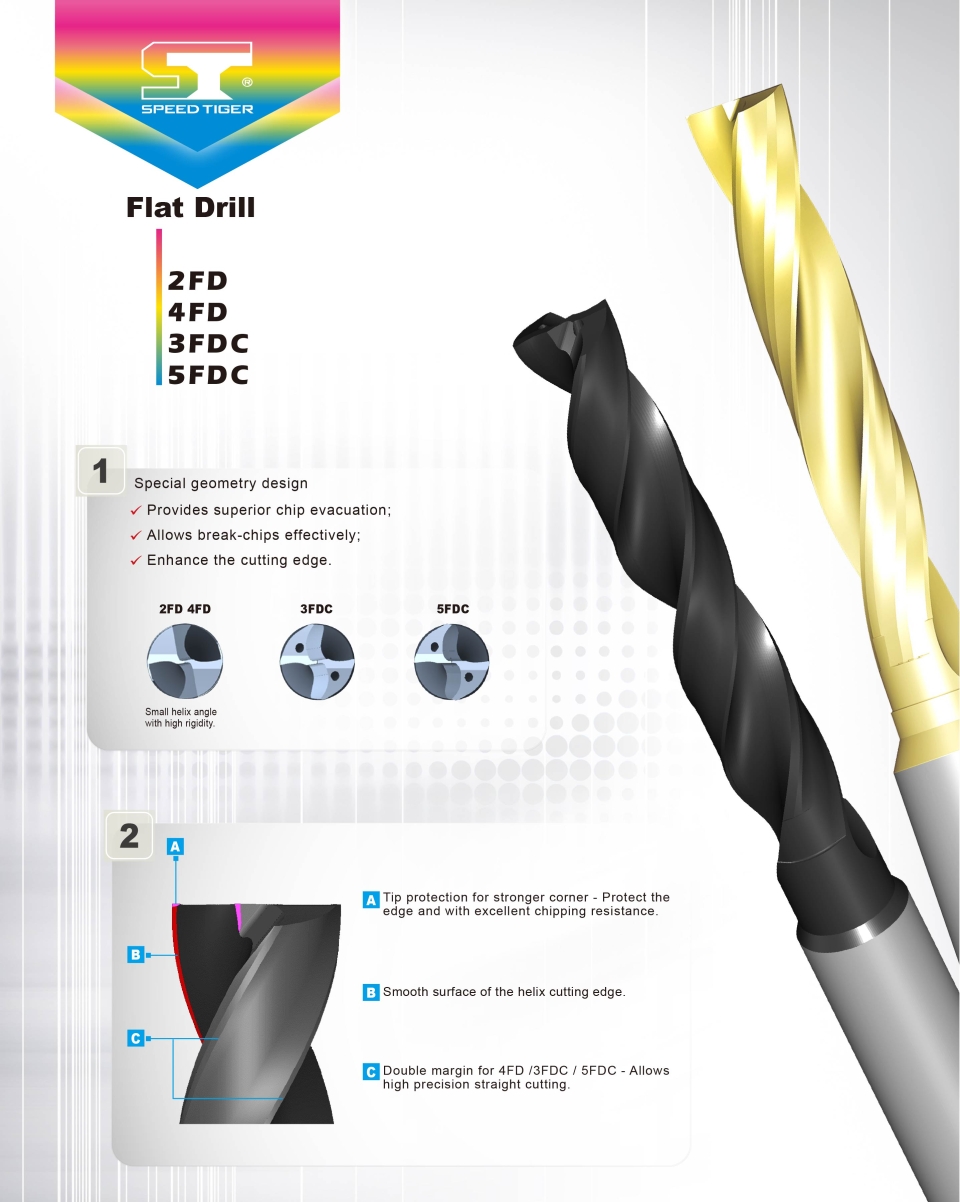

►2FD ►4FD ►3FDC ►5FDC

♦Size Range: Ø3-16mm // Ø3-14mm

♦Point Angle: 180º

Features

1. Special geometry design

-Provides superior chip evacuation

-Allows break-chips effectively

-Enhance the cutting edge

2. A. Tip protection for Stronger Corner -Protect the edge and with excellent chipping resistance.

B. Smooth surface of the helix cutting edge.

C. Double margin for 4FD /3FDC / 5FDC - Allows high precision straight cutting.

3. High-Efficiency Drilling in Various Types of MachiningApplicable for a multitude of drilling applications such as inclined surface, curved surface, flatbottom hole, eccentric hole, and more.

Application

◎ Excellent ○ GoodCoating Carbon steel,

Alloy steelPre-harden steel

~45HRHigh-hardened

~50HRCStainless steel Cast iron Cooper alloy Aluminum alloy Titanium alloy Nickel/

Inconel alloynACRo ◎ ○ ○ ○ ZrN-A ○ ◎ ○ ○ ○ ○

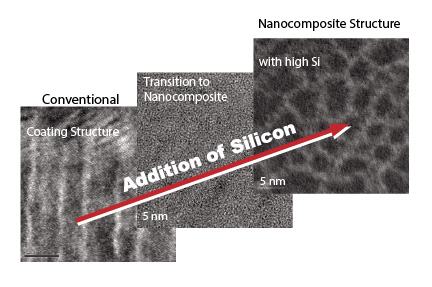

PVD Coating (nACRo & ZrN-A)  nACRo Nanocomposite coating processBy deposition very different kinds of materials,the components (like Ti, Cr, Al in the first group,and Si in the other) are not mixed completely, and 2 phases are created. The nanocrystalline TiAlN- or AlCrN-grains become embedded in theamorphous SiN-matrix and the nano-composite structure develops.

nACRo Nanocomposite coating processBy deposition very different kinds of materials,the components (like Ti, Cr, Al in the first group,and Si in the other) are not mixed completely, and 2 phases are created. The nanocrystalline TiAlN- or AlCrN-grains become embedded in theamorphous SiN-matrix and the nano-composite structure develops.

Silicon increases the thoughness and decreases the internal residual stress of the coating. The increasing of the hardness is generated by the structure only, the SiN matrix enwraps the hard grains and avoids growing of their size.

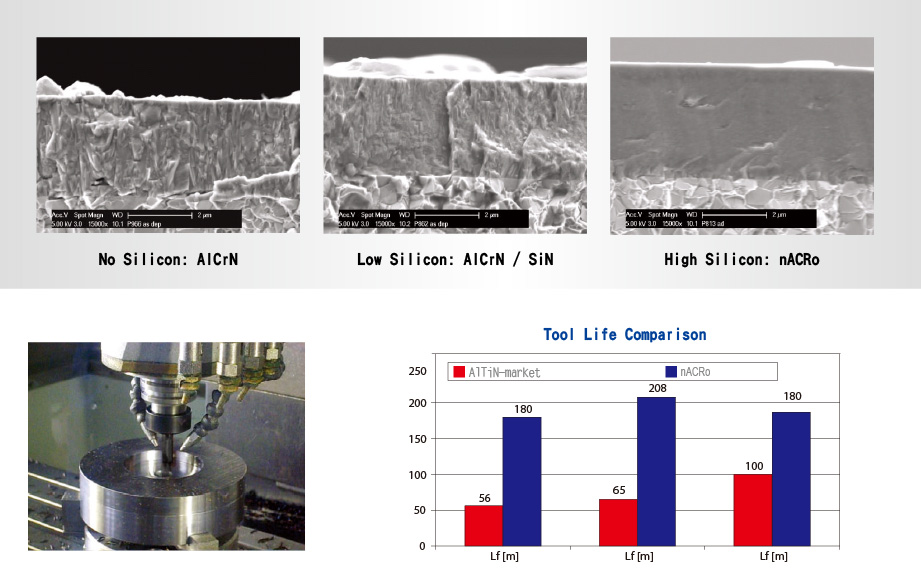

- Contain Si membrane, oxidation start temperature : 1,100℃.

- Nano grade coating, better surface finish

- Extremely high nano hardness, extremely high adhesion.

- Better protection for tools, reduction of production cost.

Carbide End Mills Ø10mm, z=4, steel 34CrNiMo6 (30 HRC), Coolant: Air; Minimum lubrication

- Tested tools: 2x4 - Source: Carmex, Maalot, ISR

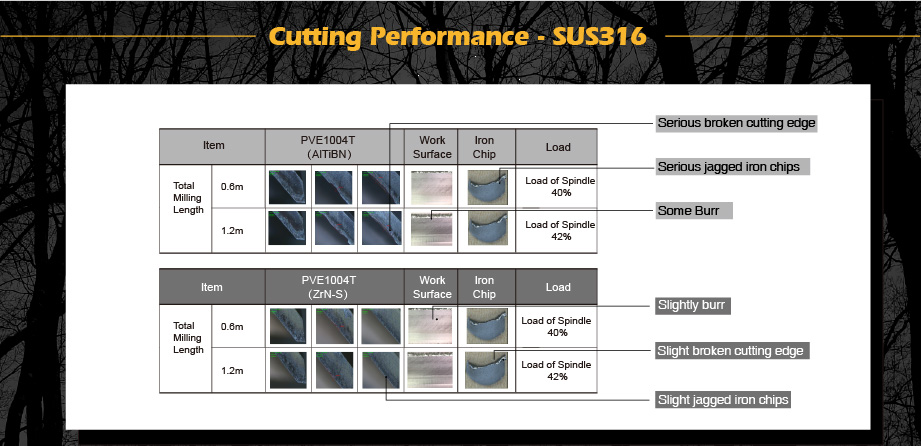

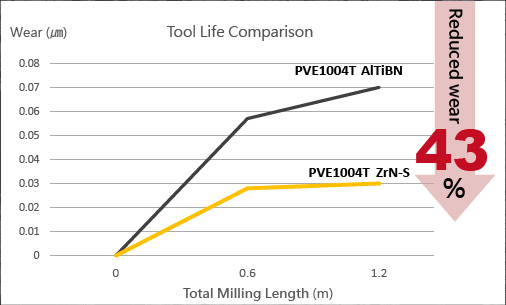

Parameter Tool(Coating) PVE 1004 ZrN-S Cutting Material SUS316 Rotation Speed (S) 2644 rpm Milling Speed (Vc) 100 m/min Feed Rate (F) 646 mm/min Depth of cut ap=10mm / ae=10mm (Fz) Feed of teeth 0.062 Machine YCM FV102A Holder BT40 Shrink fit holder The length of Tool Extend 37mm Cooling Way Water

Coating Total Milling Length (m) 0.6m 1.2m ALTIBN 0.057µm 0.07µm ZrN-S 0.0µm 0.03µm

Package & Shipping

Delivery :

Generally, it is 5-7 days if the goods are in stock.

It is 15-20 days if the goods are not in stock, it is according to quantity.

https://www.speedtigertools.com/inquiry/

The Guide to Buying Carbide Drill Bits, Choose the right one for your job! -

►2SN & 4SN- without coolant hole

Mode Photo Coolant Hole Helix Angle Point Angle Coating Diameter Spec. Cutting Condition 2FD

X 30° 135° nACRo

ZrN-A3.0mm~16.0mm Download Download 4FD

X 30° 135° 3.0mm~14.0mm Download 3FDC

O 28~30° 140° 3.0mm~14.0mm Download Download 5FDC

O 28~30° 140° 3.0mm~12.0mm Download -

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media

-