PRODUCTS

SH - Super High Hardness & High Speed

Product Number:KTG, KCR, BFR

█Features: ① A new geometry is adopted to ensure rigidity and excellent R accuracy & special cutting edge. ②High efficiency ③High accuracy ④A powerful roughing is available. ⑤Highly accurate finish cutting is possible. ⑥Developed Nano SH Coating of high adhesion and high hardness is adopted. █Application: Excel at high hardness steel.

-

Features

- Long life for high hardness steel

- Super high hardness, super high speed cutting

- Super high adhesion coating & super high hardness coating

Super Coating SH

Nano-composite coating which is improved the adhesion property without making the abrassive property lower bt new coating material of nano-

crystal

Excellent cutting is reached in machining plastic moulds,especially in NAK steels with over two times in machining efficiency. Long tool life and precision machining in carbon steels, alloy steels, NAK55 etc.

Dry cutting applicable, because of less cutting heat by improving friction property very much and high speed cutting applicable.

Features

Developed NaNo SH Coating of high adhesion and high hardness is adopted.- The tool life has drastically been improved

- Long Tool Life

- High Accuracy

- Less dimensional change, It’s suitable for finishing

A new geometry is adopted to ensure rigidity and excellent R accuracy & specially cutting edge.- High Accuracy

- High Efficient

- A powerful roughing is available

- Highly accurate finish cutting is possible

- The tool exhibits it's power to various materials from pre-harden steel (45 HRC class to high hardness 65 HRC class).

- Especially for tp make possible the high performance roughing process on molds milling (3 times or more efficient than of a general radius endmill).

- R tolerance: ±0.01mm.Highly accurate finish cutting is possible.

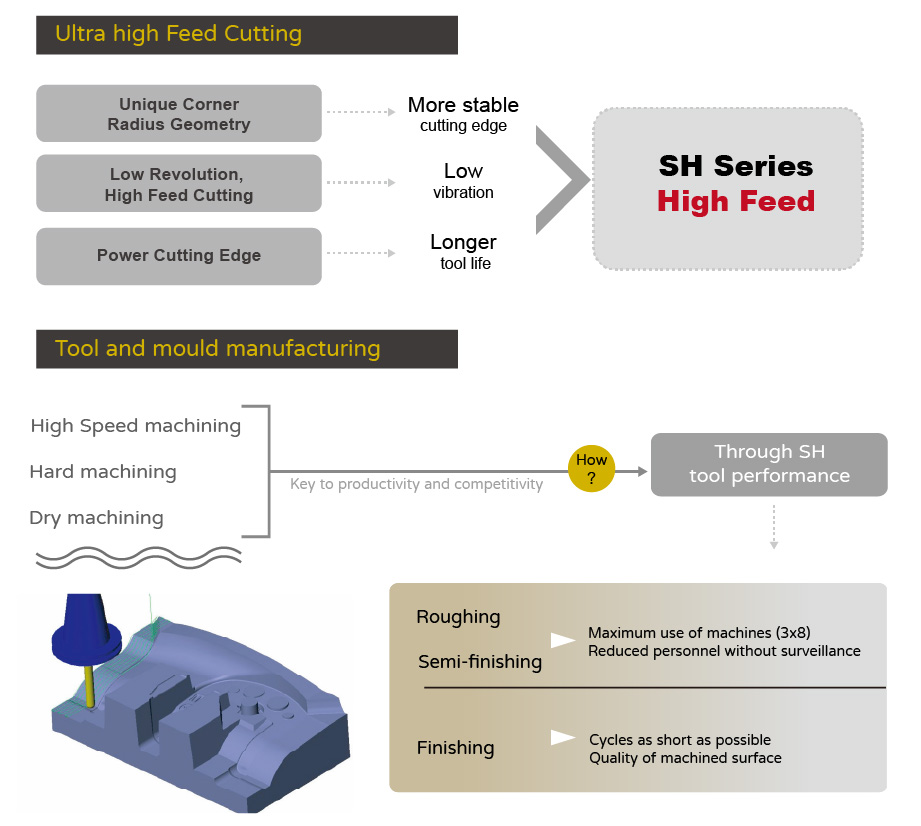

Ultra high feed cutting- Unique corner radius geometry -> More stable cutting edge

- Low Revolution, High Feed Cutting -> Low vibration

- Power Cutting Edge -> Longer tool life

Through SH tool performance :- High Speed machining

- Hard machining

- Dry machining

Maximum use of machines (3x8)

Reduced personnel without surveillance

Finishing

Cycles as short as possible

Quality of machined surface -

SH Coating

Coating Material System Application Typical Thickness (µm) Hardness (HV) Oxidation Temp. (°C) Coefficient of Friction Color AlTiN SH Multilayer Nano High speed machining, High Hardness 2~4 3600 1200 0.34 Golden AlTiN SS Multilayer Nano High speed machining, dry or wet cutting, soft steel 2~4 3300 900 0.30 Silver

Why do we coat “Super Hard Altin”? We called SH Altin!BFR demand coatings SH because SH coatings:

Reduce customers costs- Longer tool life

- Less manufacturing down time

- Tools work faster / more production per hour

- Reduced tool inventories

- Reduction or elimination of coolants / release agents

Improve quality- Less scrap

-

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media