PRODUCTS

SUS+ Series - Anti-Vibration

Product Number:SUS+, SUSL+

The SUS+ series, which combines the three elements of material, grinding, and coating, provides excellent wear resistance. █Features:① The long edge passes through the center edge, the end tooth has a large chip removal space, and the geometric design is aimed at slot machining and ramp milling. ②Special flute geometry to improve chip disposal. ③Unequal flute spacing and irregular helixes, ensure stable machining of difficult-to-cut materials and achieve a high-efficient performance. ④ZrN-A coating passed through the NANO level, can increase the hardness and wear-resisting, also effectively segregate the stick between the work piece and cutting tool. █ Application: not limited to stainless steel processing, and has an even better service life in general processing.

-

Features  Unceasing transcend self Appear perfect limit

Unceasing transcend self Appear perfect limit

The SUS+ series, which combines the three elements of material, grinding and coating, provides excellent wear resistance. It is not limited to stainless steel processing, and has an even better service life in general processing.

With ZrN-A coating, it provides high oxidation temperature, high hardness and anti-sticking characteristics, and can obtain stable tool life. Using this new tool can not only solve the difficulties of many stainless steel processing users who are troubled by the short and unstable tool life, but also help users who for pursuing high-speed and high-efficiency to reduce costs in difficult-to-cut materials processing.

- The long edge passes through the center edge, the end tooth has a large chip removal space, and the geometric design is aimed at slot machining and ramp milling.

- Special flute geometry to improve chip disposal.

- Unequal Flute Spacing , A≠B Irregular Helix Flutes, α≠β. Ensures stable machining of difficult-to-cut materials, and achieve high efficient performance.

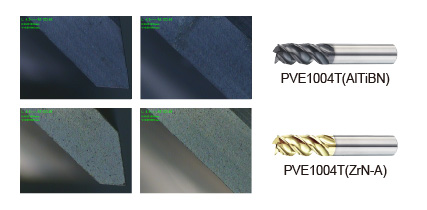

- ZrN-A coating passed through the NANO level,can increase the hardness and wear-resisting,also effective segregate the stick between the work piece and cutting tool.

-

ZrN-A Coating

Block resistance- Suitable for High Speed machining with both dry and wet cutting way.

- Hardness 2800~3000 HV

- Coefficient of friction: 0.3

- Oxidation Temp: 800~900°C

- High performance coating(Light golden)

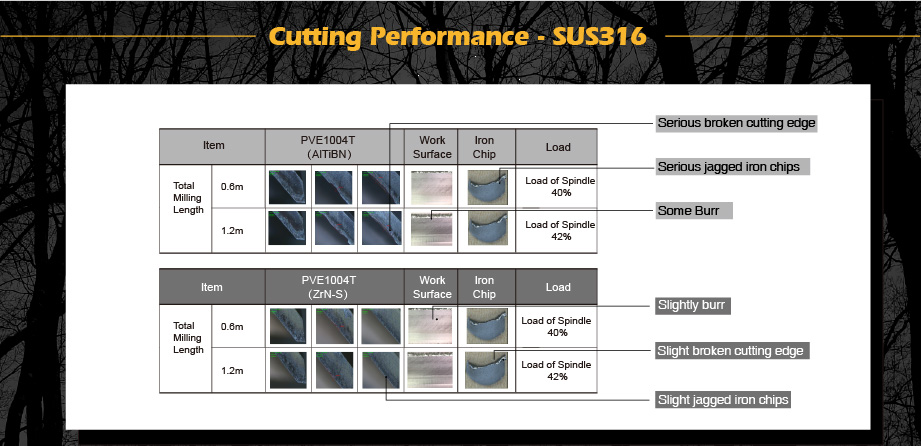

Measured comparison-SUS316

Before the tool is used

Parameter Tool(Coating) PVE 1004 ZrN-A Cutting Material SUS316 Rotation Speed (S) 2644 rpm Milling Speed (Vc) 100 m/min Feed Rate (F) 646 mm/min Depth of cut ap=10mm / ae=10mm (Fz) Feed of teeth 0.062 Machine YCM FV102A Holder BT40 Shrink fit holder The length of Tool Extend 37mm Cooling Way Water

Parameter Tool(Coating) PVE 1004 ZrN-A Cutting Material SUS316 Rotation Speed (S) 2644 rpm Milling Speed (Vc) 100 m/min Feed Rate (F) 646 mm/min Depth of cut ap=10mm / ae=10mm (Fz) Feed of teeth 0.062 Machine YCM FV102A Holder BT40 Shrink fit holder The length of Tool Extend 37mm Cooling Way Water

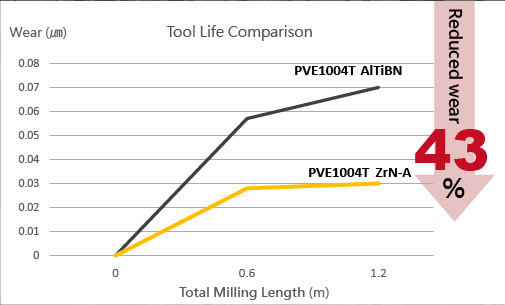

Coating Total Milling Length (m) 0.6m 1.2m ALTIBN 0.057µm 0.07µm ZrN-A 0.0µm 0.03µm

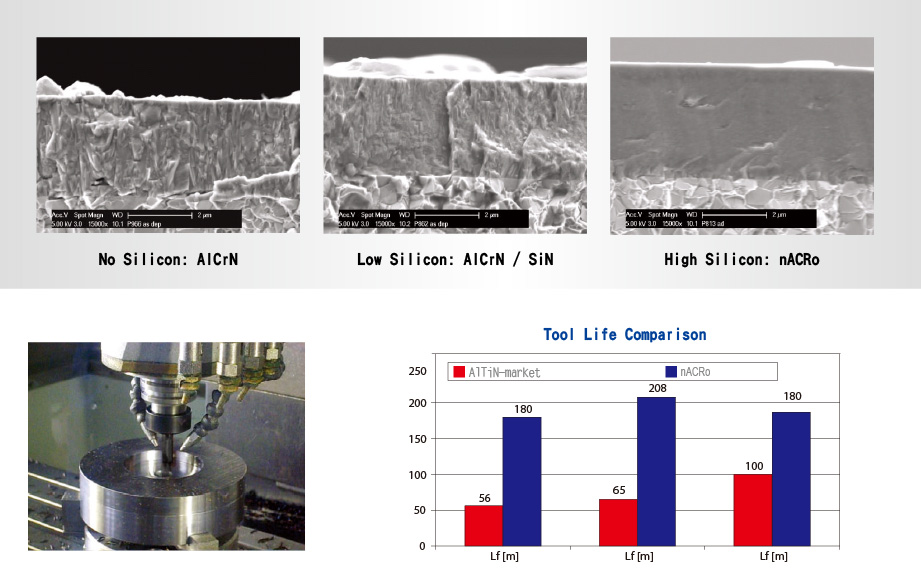

nACRo Coating

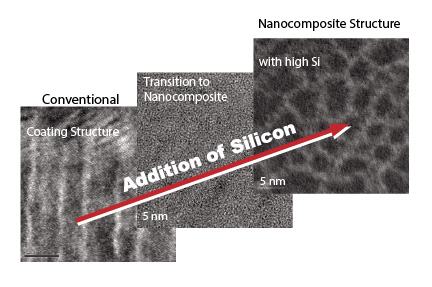

nACRo Nanocomposite coating processBy deposition very different kinds of materials,the components (like Ti, Cr, Al in the first group,and Si in the other) are not mixed completely, and 2 phases are created. The nanocrystallineTiAlN- or AlCrN-grains become embedded in theamorphous SiN-matrix and the nano-composite structure develops.

Silicon increases the thoughness and decreases the internal residual stress of the coating.

The increasing of the hardness is generated by the structure only, the SiN matrix enwraps the hard grains and avoids growing of their size.- Contain Si membrane, oxidation start temperature : 1,100℃.

- Nano grade coating, better surface finish

- Extremely high nano hardness, extremely high adhesion.

- Better protection for tools, reduction of production cost.

Carbide End Mills Ø10mm, z=4, steel 34CrNiMo6 (30 HRC), Coolant: Air; Minimum lubrication

Carbide End Mills Ø10mm, z=4, steel 34CrNiMo6 (30 HRC), Coolant: Air; Minimum lubrication

-Tested tools: 2x4 - Source: Carmex, Maalot, ISR -

Spec. Download

Cutting Condition Download

MODE Diameter Flute

LengthFull

LengthShank

DiameterFlutes SUS+0304 3 7 50 6 4 SUS+0404 4 10 50 6 4 SUS+0504 5 12 50 6 4 SUS+0604 6 13 50 6 4 SUS+0804 8 19 60 8 4 SUS+1004 10 22 75 10 4 SUS+1204 12 26 75 12 4 SUS+1604 16 32 100 16 4 MODE Diameter Flute

LengthFull

LengthShank

DiameterFlutes SUSL+0604 6 24 75 6 4 SUSL+0804 8 32 100 8 4 SUSL+1004 10 40 100 10 4 SUSL+1204 12 48 115 12 4 SUSL+1604 16 64 150 16 4 -

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media