PRODUCTS

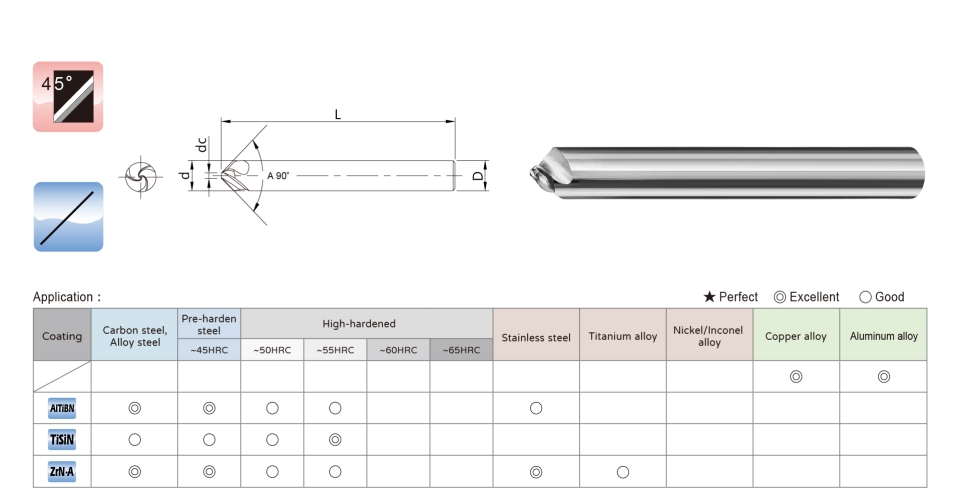

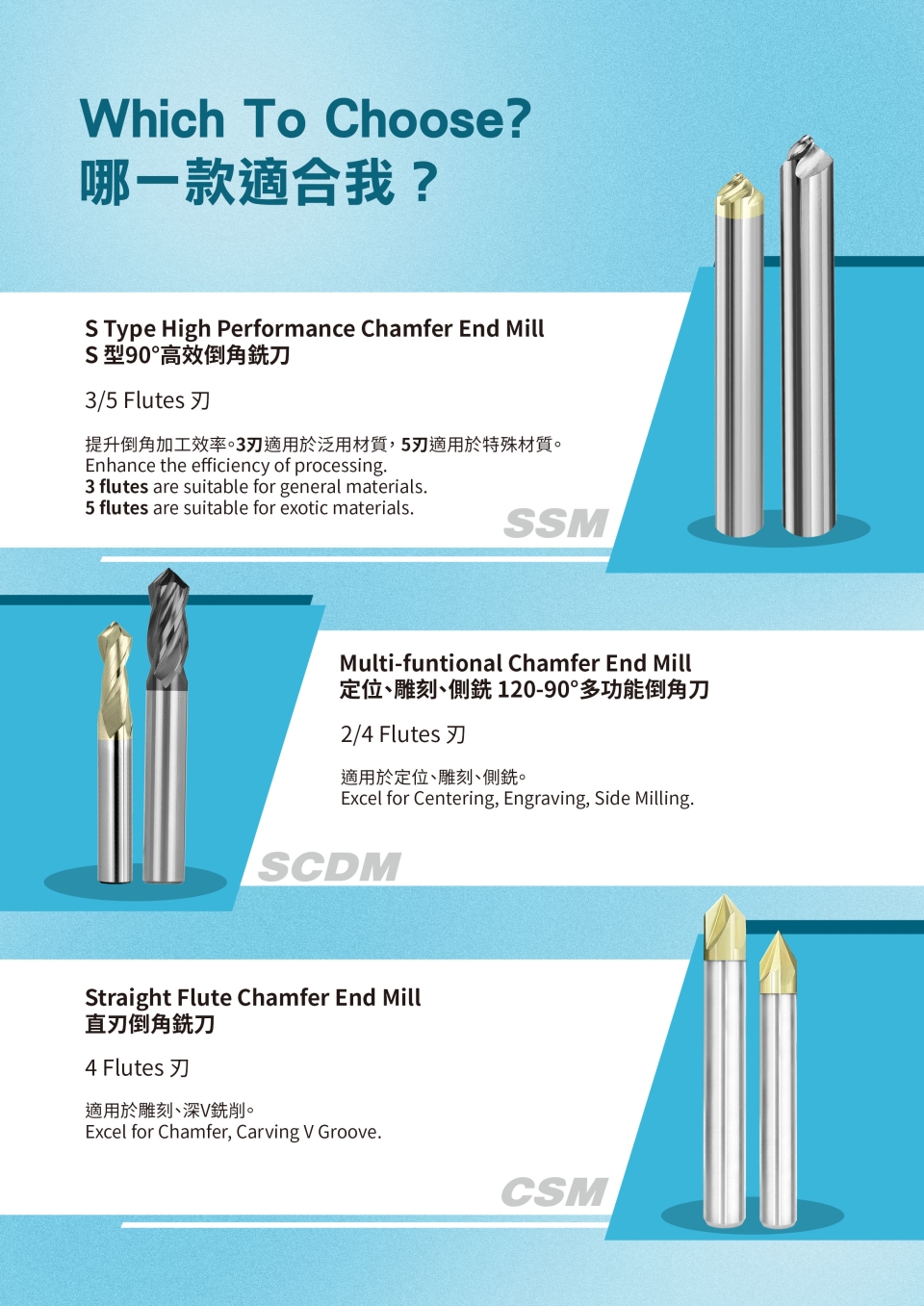

High Performance S-Flute Chamfer Mill - 3 Flutes

Product Number:SSM 90°

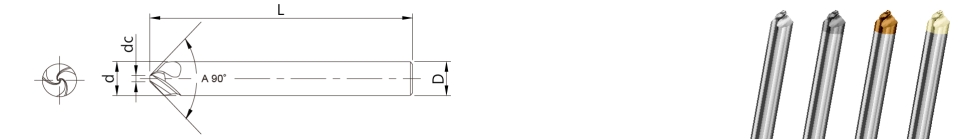

① Special tool geometry enables efficient milling of beautiful surfaces. ② With different coatings, it can be used on general steel, stainless steel, and titanium alloy, etc.

-

SSM 3 - Flute Specification / Helix 45°

MODE Diameter (d) A Angle dc Shank Diameter (D) Full Length (L) No. of

flutes (Z)Coating / ALTIBN TISIN ZrN-A SSM0603-90 6 90° 0.9 6 50 3 .00 .01 .02 .03 SSM0803-90 8 1.2 8 60 3 .00 .01 .02 .03 SSM1003-90 10 1.5 10 75 3 .00 .01 .02 .03 SSM1203-90 12 1.8 12 75 3 .00 .01 .02 .03

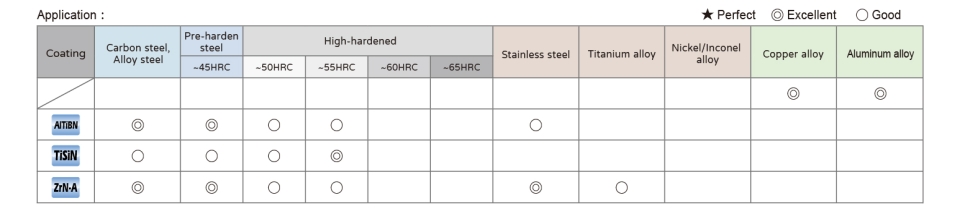

Coating Options

- Uncoated (.00): for Aluminum, cooper alloy.

- AlTIBN (.01): for Steel

- TiSiN (.02): for High-Hardened Steel

- ZrN-A (.03): for Stainless Steel, Titanium

With different coatings, it can be used on general steel, stainless steel and titanium alloy, etc.

What is the use of chamfer mills?

Chamfer Mills are designed for deburring, beveling, countersinking, and chamfering in machining operations. They also enhance tool life and finishing for profiling. Many machining operations leave a burr or sharp edge on the workpiece, making chamfer mills one of the common tools for addressing this issue. They are used for standard chamfering operations, deburring, chamfering in small grooves and holes, and can be employed on CNC or manual milling machines.

Purchase 45°, 60°, 90°, 120° angle Chamfer Mills from Speed Tiger, one of the leading carbide end mill manufacturers in Taiwan. Our Chamfer Mills series products all offer ALTIBN and AlTiSiN Coating, designed to improve wear and heat resistance. -

Specification & Cutting Condition Download

What is the use of chamfer mills?

Chamfer Mills are designed for deburring, beveling, countersinking, and chamfering in machining operations. They also enhance tool life and finishing for profiling. Many machining operations leave a burr or sharp edge on the workpiece, making chamfer mills one of the common tools for addressing this issue. They are used for standard chamfering operations, deburring, chamfering in small grooves and holes, and can be employed on CNC or manual milling machines.

Purchase 45°, 60°, 90°, 120° angle Chamfer Mills from Speed Tiger, one of the leading carbide end mill manufacturers in Taiwan. Our Chamfer Mills series products all offer ALTIBN and AlTiSiN Coating, designed to improve wear and heat resistance.

-

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media

-