PRODUCTS

KK Series - High Speed Plugging + Slotting + Side milling

Product Number:KKH, KKM, KKF, KKR

█Features: ①Two flutes with four teeth, four flutes with eight teeth, high performance. ② High efficient, double tooling life, saving time and cost. ③ Geometric appearance of the end mill creates longer tooling life, low vibration, high feed rate, and smooth surface. ④Low vibration and cutting flute sharpness with a more lasting edge make a contribution to the improvement of surface accuracy.

-

Features

Patent of Germany No:Nr.20 2006 014 089.1

Apply in the multinational patent.

Patent of Japan No:Nr.3145278

Apply in the multinational patent.

Patent of China No:ZL 2006 2 0124295.4

Apply in the multinational patent.

Patent of Taiwan No:M 303075

Apply in the multinational patent.

Features

Two flutes with four teeth, Four flutes with eight teeth, High performance, High efficient, double tooling life, saving time and cost. Adding second cutting teeth near the major cutting teeth will improve the cutting performance greatly. The meaning of this new development is like the second razor blade innovating the shaving experience. KK is developed according to the innovation of razor. The characteristic of KK endmill is 2 flutes with 4, 3 flutes with 6 teeth, 4 flutes with 8 teeth, 5 flutes with 10 teeth. Geometric appearance of endmill creates longer tooling life, low vibration, high feed rate, and smooth surface. The reason of longer tooling life is when the major tooth wear, the second tooth is still shape. Longer tooling life also benefit to reduce the horizontal vibration. Close distance between two teeth make the cutting edge produce irregular touch with working material and reduce harmful resonance. It contributes to control vibration that changes of helix angle between every group tooth .

Reduction of cutting load of per teeth, 2 teeth enable increase feed rate (for each group tooth , the cutting load of second tooth is less than first tooth so the cutting area of econd is smaller than first ones)

Low vibration and cutting flute sharpness with more lasting edge make a contribution to improvement of surface accuracy.

Stocked item: Dia 6mm~25mm

Coating:- KKH nACo

- KKM Si

- KKF, KKR nACro

First Diameter (Roughing) Second Diameter (Finishing) Diameter Tolerance (Unit:mm) Tolerance (Unit:mm) 6mm -0.08~-0.10 +0.00~-0.02 8mm -0.10~-0.12 +0.00~-0.02 10mm -0.12~-0.15 +0.00~-0.02 12mm -0.15~-0.18 +0.00~-0.02 16mm -0.20~-0.24 +0.00~-0.02 20mm -0.24~-0.30 +0.00~-0.02 -

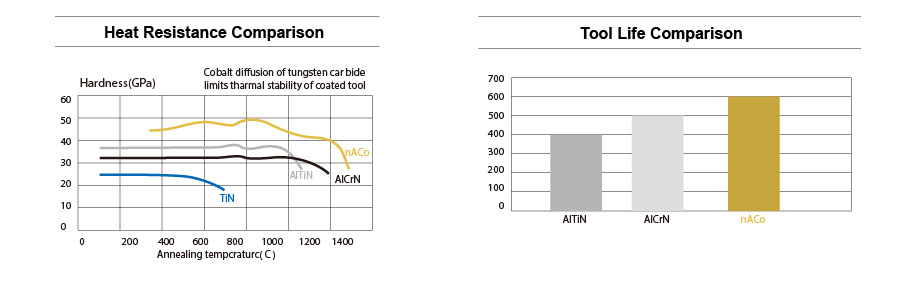

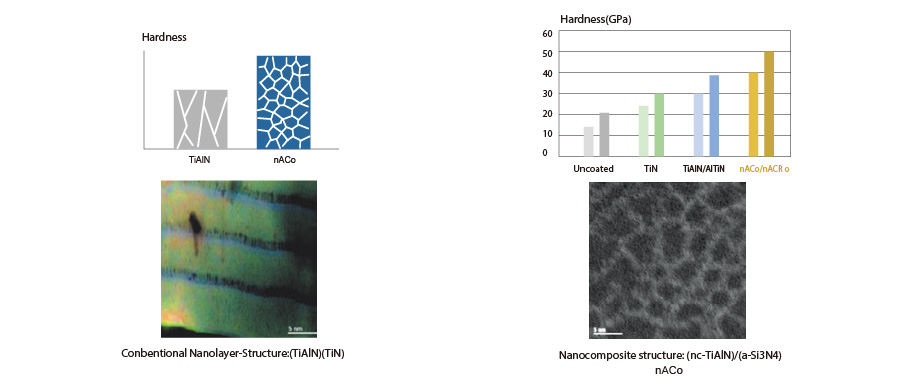

nACo Coating

nACo Nanocomposite coating process.- Perfect coating structure.

- High hardness.

- High adhesion.

- Adding Si into nACo structure makes atom structuremore completed with high hard-wearing and tools with more longer life.

AlTiN vs nACo comparisonS.T Coating Typical Thickness(£g) Nanohardness up to (GPa) Max Service Temp(¢J) Friction coefficient AlTiN 2~4 35 800 0.6 nACo 2~4 45 1200 0.35

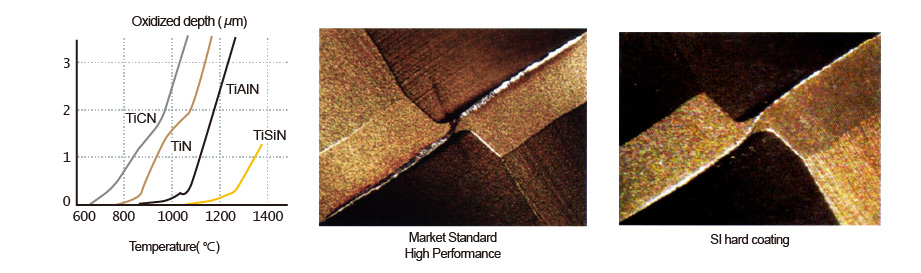

TiSiN Coating

New Nano-composite coating material achieves extraordinary heat resistance and hardness. This is attained due to the new composite layer, consisting of nano-crystal material (Oxidizing temperature:1100℃, Layer hardness:HV 3600). Achieves extraordinary performance in high-speed cutting, and high efficient machining of hardened steel, machining efficiency is more than twice as effective as other manufacturers solid carbide end mills.

Ensuring long life and reliability in hardened steel applications HRC45~55 material examples:1.2080, 1.2344, and 1.2379, ASP Power Steels, High Speed Steels.

The coating generates less heat during cutting; therefore it is well suited to dry machining conditions.

Newly developed TiSiN Coating has excellent oxidation-resistant properties, this achieves:

High speed cutting of hard steels = High Efficiency

Improvement in tool life = Lower tooling costs The newly designed flute geometry increases rigidity, with the improved high radius accuracy producing higher tolerance, and smoother surface finish.

Direct Milling of hardened steel is now possible = Faster production times.

Patent of Taiwan No : I 280288 (the method of tool surface hardening)

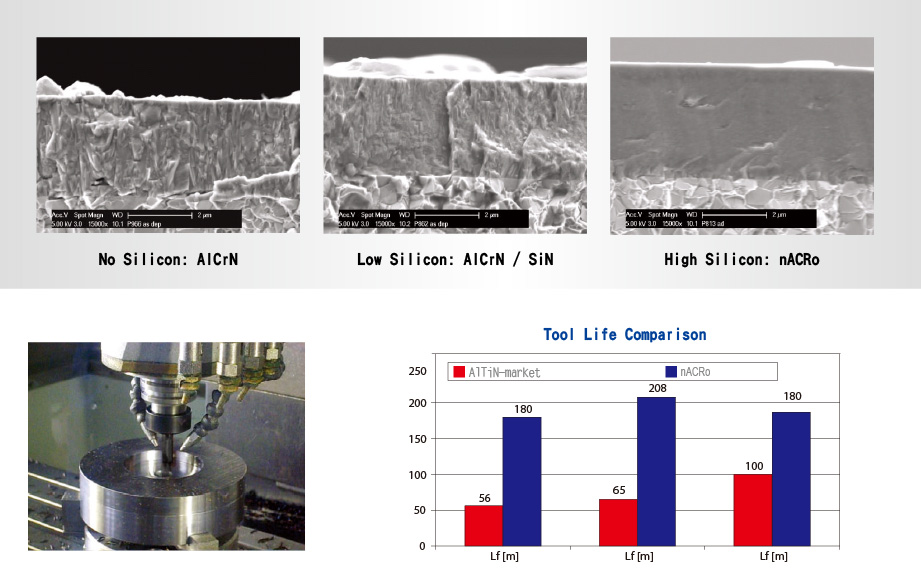

nACRo Coating

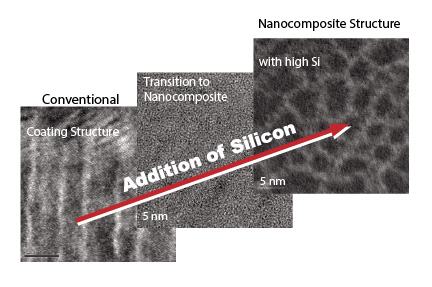

nACRo Nanocomposite coating processBy deposition very different kinds of materials,the components (like Ti, Cr, Al in the first group,and Si in the other) are not mixed completely, and 2 phases are created. The nanocrystallineTiAlN- or AlCrN-grains become embedded in theamorphous SiN-matrix and the nano-composite structure develops.

Silicon increases the thoughness and decreases the internal residual stress of the coating. The increasing of the hardness is generated by the structure only, the SiN matrix enwraps the hard grains and avoids growing of their size.- Contain Si membrane, oxidation start temperature : 1,100℃.

- Nano grade coating, better surface finish

- Extremely high nano hardness, extremely high adhesion.

- Better protection for tools, reduction of production cost.

Carbide End Mills Ø10mm, z=4, steel 34CrNiMo6 (30 HRC), Coolant: Air; Minimum lubrication

Carbide End Mills Ø10mm, z=4, steel 34CrNiMo6 (30 HRC), Coolant: Air; Minimum lubrication

- Tested tools: 2x4 - Source: Carmex, Maalot, ISR -

Series Introduction Download

For detailed cutting condition, please contact us, thank you. (sale@speedtiger.com.tw)

TypeMode Flutes Diameter Photo Dimension Cutting Condition Roughing & Finishing Type KKH 2 / 3 / 4 2Flutes-6mm~25mm

3Flutes-6mm~25mm

4Flutes-10mm~25mm

Download Download Roughing & Finishing Type KKM 2 / 3 / 4 2Flutes-6mm~25mm

3Flutes-6mm~25mm

4Flutes-10mm~25mm

Download Download Roughing & Finishing Type KKF 2 / 3 6mm~20mm

Download Download

Roughing & Finishing Type KKR 2 / 3 6mm~25mm

Download

Download

-

-

● Headquarters

TEL : +886-4-2350-3022

FAX : +886-4-2350-3083

Mail : sale@speedtigertools.com

Address: No.10, Jingke 2nd Rd., Nantun Dist., Taichung 40852, Taiwan

Worldwide Sales Network

Worldwide Sales Network

● Social Media