SOLUTIONS

Knowledge

The Guide to Buying Carbide Drill Bits, Choose the right one for your job!

The Guide to Buying Carbide Drill Bits, Choose the right one for your job!

If you work in an industry that relies on tools to get the job done, you’ll already know just how important a drill is for your overall success. But what you may not know is that the drill bit is arguably just as important. You may have a top-quality drill, but if the drill bit is subpar, then your work will suffer. Fortunately, that’s not a problem that you need to deal with. Armed with the correct information, you can ensure that you always have a drill bit that’ll aid, rather than hinder your project. So what’s the best option? Most experts agree that carbide drill bits are the way to go. We’ve put together a handy carbide drill bits buying guide, so you can know exactly what piece you need for the job.

You will learn the basic and useful knowledge of Carbide Drill Bits:

- What are Carbide Drill Bits?

- Carbide Drill Bits Constructions

- Common Types of Carbide Drill Bits

- Carbide Drill Bits Uses and Application

- Exploring the Advantages of Carbide Drill Bits

- Expert Tips for Buying Carbide Drill Bits

- Speed Tiger Best Carbide Drill Bits Info.

1. What are Carbide Drill Bits?

Let’s begin by looking at what a carbide drill bit is. ‘Carbide’ refers to the material that the drill bit is made from. There are plenty of different drill bit materials, but they’re not all appropriate for all jobs. The most common option is the HSS drill bit, which will likely have been the drill bit you used if you completed a home DIY project. They’re handy and effective, but only in certain situations; you typically won’t find HSS drill bits used in industrial settings.Carbide Drill Bits Materials? Is it harder than HSS?

Industrial jobs typically used carbide drill bits because of their strength. They’re made from a mixture of tungsten and carbon, two very strong materials that combine to create a drill bit that can cut through items that would break an HSS drill bit, such as concrete, tile, and others.2. Carbide Drill Bits Constructions

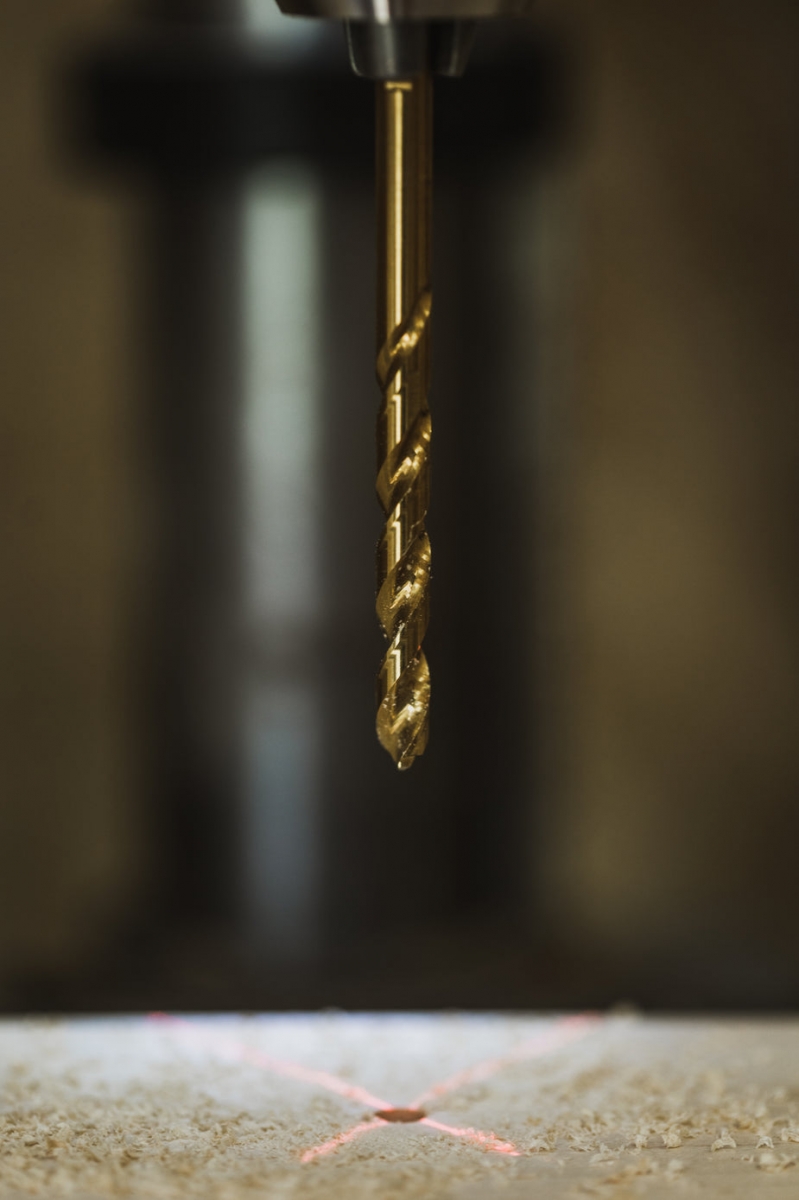

You don’t have to look at a carbide drill bit for too long before you notice that they’re not quite the same as other drill bits you may have come across. That’s because the way they function is slightly different to drill bits made of other materials. Carbide drill bits are used to drill holes in hard materials, and they do this by punching the material until it is crushed. The bit moves up and down repeatedly (at a rate too fast for the eye to see) and, in the process, transfers the debris of the punched hole outside.You can get carbide drill bits cut into a specific shape, custom-made for the intended use, but there are also plenty of standard options available, too — for example, twist, spade, hole saw, and step bit. It’s important to remember that carbide largely just refers to the material; if you see any drill shape, it’ll probably be available in carbide. You can also get carbide drill bits in virtually any size, anywhere from a few inches all the way to sixty inches. If you need a greater length than that, you can get one custom-made — there’s no limit to how long the bits can be.

3. Common Types of Carbide Drill Bits.

-

Type 1: Twist Bit

-

Type 2: Spade Bits and Hole Saws

-

Type 3: Step Bit

★ Learn more Carbide Drill Bits information & Tips:

Different Types of Drill Bits (3 Steps Guide for Uses & Choosing)

When Should I Use Flat Drills (Flat Bottom Tools)?

4. Carbide Drill Bits Uses and Application

You’ll find carbide drill bits being used in a wide range of industries. They’re generally not used in domestic projects because they’re not needed. But they’re a mainstay in tool cutting, PCB manufacturing, woodwork, gas and oil projects, and masonry. Essentially, you’ll find carbide drill bits in any industry when strength and/or precision drilling is required. In PCB manufacturing, for example, they’re used for accurately drilling in small sizes; in oil and gas projects, they’re used to drill through some of the earth’s hardest materials; in masonry, they’re used to drill through concrete and brick.5. Exploring the Advantages of Carbide Drill Bits

Carbide drill bits stand out in the realm of drilling tools, offering numerous advantages that make them a worthwhile investment. In a market flooded with various options, these drill bits, made from a powerful combination of tungsten and carbon, prove to be a superior choice. Let's delve into the key advantages that make carbide drill bits a standout option for professionals and enthusiasts alike.-

Strength of Carbide Drill Bits

-

Precision in Drilling

-

Long-Lasting Durability

-

Versatility Across Industries

-

Environmental Friendliness

In summary, the exceptional strength, precision, durability, versatility, and environmental friendliness of carbide drill bits make them a standout choice in the world of drilling tools. Whether tackling industrial projects or engaging in creative endeavors, opting for carbide ensures reliable and efficient drilling performance.

6. Expert Tips for Buying Carbide Drill Bits

When venturing into the world of carbide drill bits, it's crucial to make informed decisions based on the specific requirements of your project. Here are expert tips to guide your purchase and ensure you acquire the right carbide drill bit for your needs:-

Tip 1: Consider Your Project Requirements

-

Tip 2: Size Matters - Choose Appropriately

-

Tip 3: Delve into Bit Length and Special Features

By adhering to these expert tips, you'll navigate the carbide drill bits market with confidence, making informed decisions tailored to the intricacies of your drilling projects. Remember, precision in selection ensures optimal performance and longevity of your carbide drill bits, making them a valuable asset in your toolkit.

7. Speed Tiger Best Carbide Drill Bits Info.

If you’re looking for high-quality carbide drill bits, then take a look at the products we offer here at Speed Tiger. We have a range of carbide drill bits available, including various point angles, size ranges, and drill depths.-

Carbide Drill Bits for Stainless Steel

SN -- Point Angle: 135° Drill Depth: 3xD / 5xD Size Range: 3mm~16mm / 3mm~14mm

SNC -- Point Angle: 140° Drill Depth: 5xD / 8xD Size Range: 3mm~14mm / 3mm~12mm

-

Carbide Drill Bits for High Hardness Steel

HD -- Point Angle: 140° Drill Depth: 3xD //Size Range: 3mm~14mm

-

Carbide Drill Bits for General Use and Cast

PK -- Point Angle: 135° Drill Depth: 5xD Size Range: 3mm~14mm

PKC -- Point Angle: 140° Drill Depth: 5xD / 8xD Size Range: 3mm~14mm / 3mm~12mm

Our products are made to superior standards, so you can have faith that your drill bit will be with you for many projects to come. Ready to make a purchase? Make an inquiry today.

Speed Tiger is the leading Carbide End mills, Drill bits manufacturer in Taiwan, we provide a large range of CNC End Mills and Drill bits, see more end mills products and our best-seller here.

| About Speed Tiger |

Speed Tiger is a professional manufacturer of Carbide Cutting Tools and offers OEM Services, having rich experience in producing carbide cutting tools and processing consultants for more than 24 years.

Established in 1998, Speed Tiger specialized in the production of precision carbide end mills, drills, turning tools, thread mills, and other tungsten carbide steel customized cutting tools. Speed Tiger crafts cutting tools at extreme nanometer precision +-2㎛ to the exact, enabling to achieve professional cutting quality.

Visit our shop to find out more, or check out our solution to continue learning.

OTHER SOLUTIONS

-

Master Guide of CNC Milling: Process & Application Posted 2023-06-07

-

Guide to Selecting an End Mill for Aluminum Machining Posted 2022-06-30