SOLUTIONS

Knowledge

10 Key Points on How to Select a Good Carbide Cutting Tools Supplier

10 Key Points on How to Select a Good Carbide Cutting Tools Supplier

Selecting the right carbide cutting tools supplier can significantly impact the efficiency and profitability of your machining operations. Here are 10 essential factors to guide your decision.

- Proven Industry Experience

- Comprehensive Product Line

- Customization Capabilities

- Product Quality and Durability

- Technological Innovation

- Competitive Pricing and Value

- Customer Support and Service

- Global Accessibility and Fast Delivery

- Sustainability Practices

- Industry-Specific Expertise

1. Proven Industry Experience

A reliable supplier should have a strong track record in the industry. Look for companies with years of experience and a demonstrated ability to adapt to technological advancements. For example, Speed Tiger, established in 1998, won the Taiwan Excellence Award for its innovative cutting tools. Their industry knowledge has enabled partnerships with top-tier manufacturers in the aerospace, automotive, mold&die sectors.2. Comprehensive Product Line

A robust product line ensures the supplier can meet all your machining needs, from roughing to finishing, across various materials like steel, aluminum, and composites. Speed Tiger offers a wide array of tools, including carbide end mills, drills, chamfer cutters, and turning tools, making it a one-stop shop for cutting solutions.Case Study: A South Korean customer required specialized tools for both roughing and finishing aluminum. Speed Tiger provided a complete solution, including DLC-coated end mills and finishing tools, helping the client achieve a flawless surface finish and 30% faster production cycles.

3. Customization Capabilities

Tailored solutions are often necessary to meet unique machining challenges. Opt for suppliers that offer customization with flexible minimum order quantities (MOQs). For instance, Speed Tiger can produce custom tools with MOQs as low as 10 pieces and deliver them within two weeks, enabling faster project turnaround.

4. Product Quality and Durability

High-quality tools ensure precision, long tool life, and reduced downtime. Look for features like anti-vibration geometries, wear-resistant PVD coatings, and tight manufacturing tolerances. Speed Tiger's cutting tools are engineered for consistent durability, backed by rigorous quality testing.

Case Study: A Thai manufacturer faced frequent tool breakages when machining hardened steel. After switching to Speed Tiger’s anti-vibration end mills, tool life increased by 40%, reducing replacement costs and machine downtime.

5. Technological Innovation

The best suppliers stay ahead of the curve with advanced technologies. Speed Tiger's proprietary PVD coating technology enhances tool performance, offering better resistance to heat, wear, and abrasion. Their constant innovation ensures users can tackle modern machining challenges effectively.Related Article: How to choose the right Coating for your End Mill?

6. Competitive Pricing and Value

Evaluate the cost-performance ratio rather than focusing solely on price. Tools that last longer and perform better can significantly reduce total machining costs. Speed Tiger delivers tools with 20-30% longer tool life compared to standard products, maximizing your ROI.Case Study: An Indian distributor needed affordable yet durable tools for a competitive market. Speed Tiger offered end mills with superior performance at mid-tier pricing, enabling the distributor to capture a larger market share while satisfying their price-sensitive customers.

7. Customer Support and Service

Exceptional customer support is a hallmark of a reliable supplier. Choose companies that offer comprehensive pre-and post-sales services. Speed Tiger's technical support team assists with tool selection, usage optimization, and troubleshooting, ensuring smooth operations for their clients.

Case Study: When a Czech client experienced issues with chatter during machining, Speed Tiger’s technical team conducted a virtual consultation and recommended their anti-vibration tools. The solution eliminated the issue and improved machining precision.

8. Global Accessibility and Fast Delivery

A global supplier with efficient logistics minimizes downtime. Speed Tiger supports clients worldwide, delivering non-stock tools within 8-12 working days, allowing businesses to maintain consistent production schedules.Production can also be expedited if there is an urgent need. For example, a Taiwan customer urgently required carbide drills for an aerospace project. Speed Tiger delivered non-stock tools within 1 week, ensuring the client met their tight production deadline without delays.

9. Sustainability Practices

Sustainability is becoming a priority in modern manufacturing. Suppliers with eco-friendly production practices, such as recycling carbide tools or reducing energy consumption, contribute to environmental responsibility. By incorporating sustainable practices, Speed Tiger aligns with global efforts toward greener manufacturing.10. Industry-Specific Expertise

Different industries have unique machining challenges. Suppliers with specialized experience in sectors like aerospace, automotive, or medical machining can better support niche needs. Speed Tiger’s versatile product range caters to diverse industries, ensuring high performance in specialized applications.Conclusion

Selecting the right carbide cutting tools supplier is critical for achieving machining precision, efficiency, and cost-effectiveness. By considering these 10 key factors and learning from these real-world examples, you can confidently choose a supplier that meets your needs and exceeds your expectations.

Explore how Speed Tiger can support your machining operations by visiting Speed Tiger's official website.

■ More Information & Tips about CNC End Mill:

Related Article: The Beginners Guide of CNC End Mill

If you are new to CNC processing, you may think that there are so many end mills in the catalog, what’s the difference? And which end mill should I use on my CNC machine? You will learn the basic knowledge of CNC end mills about End Mill Shapes, End Mill Flutes, Details of the End Mill, and End Mill Coatings.

Related Article: End Mill Cutting & End Milling - Technical Guide

End mills are a key tool for cutting, with a range of different applications. As one of the most common types of cutting tools, end mills are also unique and specifically used for the end milling process. End mill cutting and end milling are crucial in manufacturing, and being familiar with these processes and tools is a must.

Related Article: Master Guide of CNC Milling: Process & Application

If you are new to CNC milling, you have probably heard of this term but be unsure what it means. In this article, you will find all the information you will need to understand what CNC milling is, how it works, its applications, advantages, and more. Read on to discover everything you need to know about CNC milling.

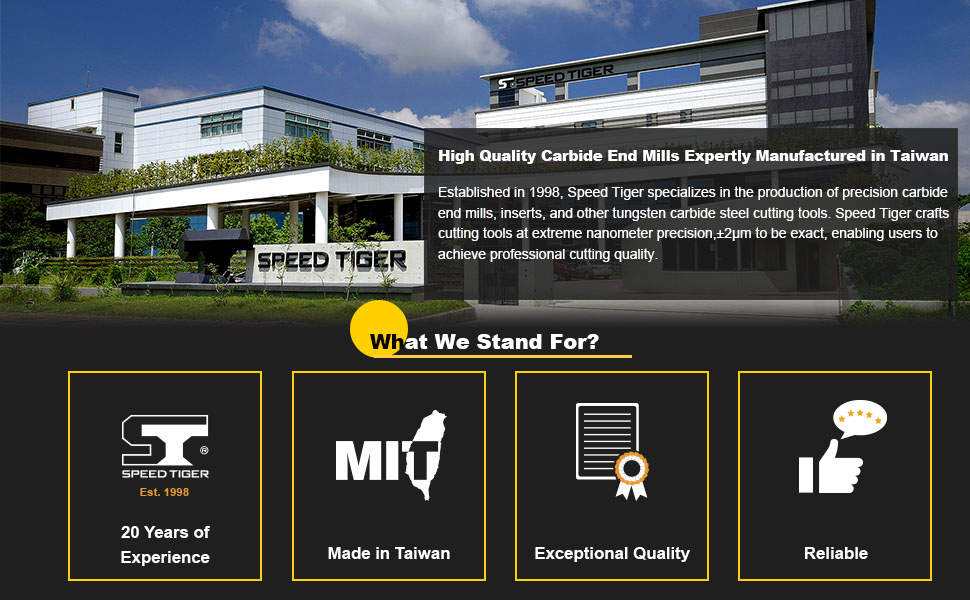

About Speed Tiger |

Speed Tiger is a professional manufacturer of Carbide Cutting Tools and offers OEM Services, having rich experience in producing carbide cutting tools and processing consultants for more than 24 years.

Established in 1998, Speed Tiger specializes in the production of precision carbide end mills, drills, turning tools, thread mills, and other tungsten carbide steel customized cutting tools. Speed Tiger crafts cutting tools at extreme nanometer precision +-2㎛ to the exact, enabling to achieve professional cutting quality.

Visit our shop to find out more, or check out our solution to continue learning.

OTHER SOLUTIONS

-

Master Guide of CNC Milling: Process & Application Posted 2023-06-07

-

End Mill Cutting & End Milling - Technical Guide Posted 2023-06-07