SOLUTIONS

Application

When Should I Use Flat Drills (Flat Bottom Tools) ?

When Should I Use Flat Drills (Flat Bottom Tools) ?

Flat Drill (or Flat Bottom Tool) is applicable for a multitude of drilling applications such as angled surface, curved surface, flat bottom hole, eccentric hole, and more.

The following graphic expression will help you understand at a glance.

Inclined Surface

Inclined Surface Curved Surface

Curved Surface Cross-Hole

Cross-Hole Counter boring

Counter boring Guide Hole

Guide Hole Inclined Exit Surface

Inclined Exit Surface Thin Plate

Thin Plate Correction of Eccentric Hole

Correction of Eccentric Hole Half Hole

Half Hole Chained Hole

Chained Hole Thin Plate

Thin Plate Blind Hole for Threading

Blind Hole for Threading

Tips: When using long flute drill bits, it’s better to use a positioning hole or a guide hole in advance.

● Position Hole: 1xD to 3xD deep drilled to assure consistent and precise holes with a long drill, and the guide hole should be bigger around 0.1mm than the diameter of the drill.

● Guide Holes: In order to assure precise hole position, and the guide hole should be bigger around 0.1mm than the diameter of the drill.

In order to meet manufacturers’ various processing needs, Speed Tiger Flat Bottom Drills Series provides with the 2D and 4D, a general-purpose type that can be used for a wide range of machining; the 3D and 5D with coolant holes that can be effectively used in stainless steel application too.

The features of Speed Tiger Flat Drills (Flat Bottom Tools) :

1) Special geometry design:

- Provides superior chip evacuation.

- Allows break-chips effectively.

- Enhance the cutting edge.

2) Special flute design:

- A. Tip protection for Stronger Corner - Protect the edge and with excellent chipping resistance.

- B. The smooth surface of the helix cutting edge.

- C. Double margin for 4FD /3FDC / 5FDC - Allows high precision straight cutting.

| Related Products Info: |

Let's take a look for our huge range for Carbid Drill Bits.

- 2xD & 4xD Carbide Flat Drill - Without Coolant Hole

- 3xD & 5xD Carbide Flat Drill - With Coolant Hole

If you have any questions or needs, please feel free to contact us!

| SEND US AN INQUIRY :) |

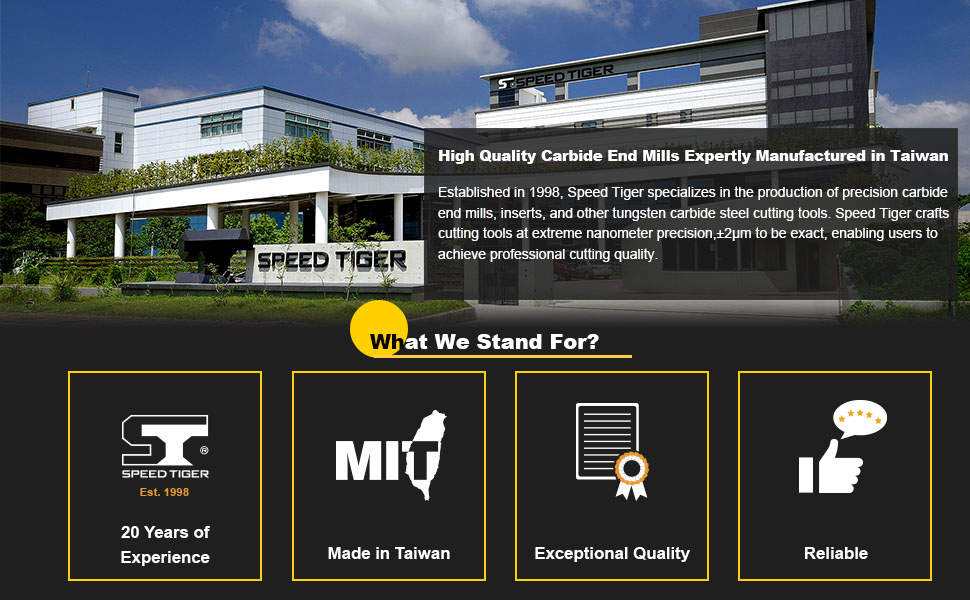

| About Speed Tiger |

Speed Tiger is a professional manufacturer of Carbide Cutting Tools and offers OEM Services, having rich experience in producing carbide cutting tools and processing consultants for more than 24 years.

Established in 1998, Speed Tiger specialized in the production of precision carbide end mills, drills, turning tools, thread mills, and other tungsten carbide steel customized cutting tools. Speed Tiger crafts cutting tools at extreme nanometer precision +-2㎛ to the exact, enabling to achieve professional cutting quality.

Visit our shop to find out more, or check out our solution to continue learning.

OTHER SOLUTIONS

-

What do End Mills coatings do Posted 2021-08-03